Optimizing Gold Ore Processing with the C6X Jaw Crusher

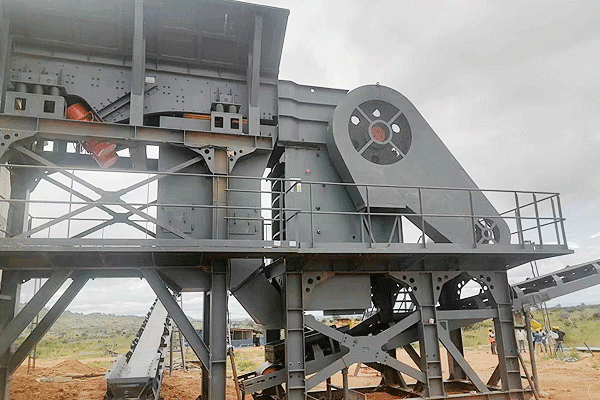

Introduction to the C6X Jaw Crusher

The C6X jaw crusher is a high-performance crushing machine designed for demanding applications in mineral processing. Its robust structure and advanced kinematics make it ideal for handling hard and abrasive materials like gold ore. With a capacity of up to 120 tons per hour (tph), this crusher ensures efficient primary crushing while minimizing operational costs. Its optimized cavity design enhances throughput, making it suitable for medium-to-large-scale gold ore processing plants.

Key Features Enhancing Efficiency

Several features contribute to the C6X jaw crusher’s superior performance in gold ore crushing. The non-welded frame construction improves fatigue resistance, extending the equipment’s lifespan even under heavy-duty conditions. Additionally, its adjustable discharge setting allows operators to fine-tune particle size distribution according to downstream requirements. The crusher’s energy-efficient motor reduces power consumption without compromising productivity—a critical factor in cost-sensitive mining operations.

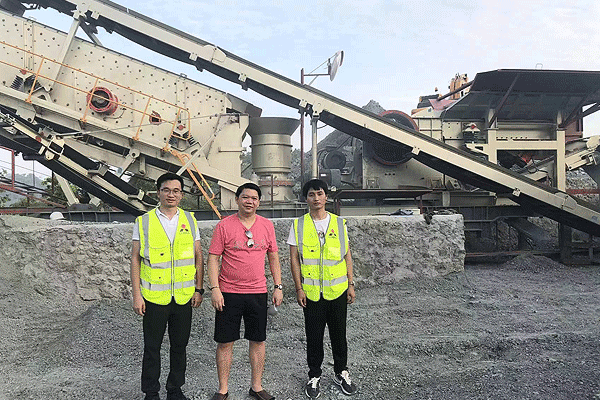

Application in Gold Ore Processing

In a 120 tph gold ore crushing plant, the C6X jaw crusher serves as the primary reduction unit, breaking down large chunks of raw ore into manageable sizes. Its high reduction ratio minimizes the need for secondary crushing stages, streamlining the overall process flow. The machine’s wear-resistant components withstand prolonged exposure to abrasive gold-bearing rock, reducing maintenance downtime and improving operational continuity—essential factors in maximizing mineral recovery rates.

Maintenance and Operational Considerations

To maintain peak performance, regular inspection of key components such as jaw plates and bearings is necessary. Proper lubrication ensures smooth operation while preventing premature wear. Operators should also monitor feed consistency to avoid uneven stress distribution across crushing surfaces—common causes of unexpected breakdowns in hard-rock applications like gold processing plants operating at 120 tph capacities or higher outputs when scaled appropriately through modular designs if required by project demands later on down their lifecycle usage periods too!

Conclusion: A Reliable Solution for Mineral Processing

The C6X jaw crusher offers an effective solution for optimizing gold ore processing workflows with its balance between durability and efficiency at scales up to 120 tph or beyond depending on configuration specifics tailored per site requirements accordingly over timeframes spanning years rather than months alone due largely thanks again partly because these machines are built tough enough handle toughest materials thrown their way day after another without fail consistently delivering results expected from top-tier equipment category leaders worldwide today!