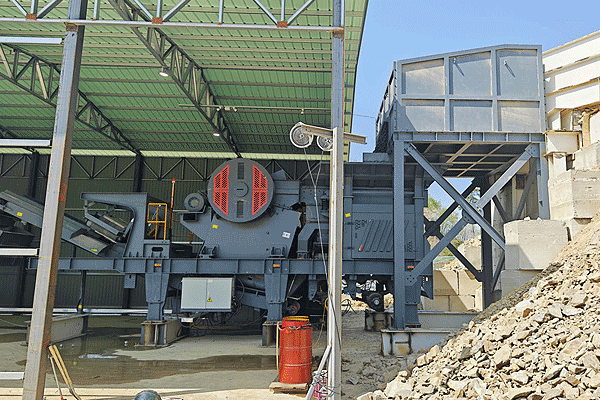

HPT Cone Crusher in a 180 TPH Andesite Crushing Plant

Introduction

The HPT cone crusher is widely recognized for its efficiency and reliability in hard rock crushing applications. In a 180-ton-per-hour (TPH) andesite crushing plant, this advanced crusher plays a crucial role in delivering consistent particle size reduction while maintaining low operational costs. Andesite, an intermediate volcanic rock, presents unique challenges due to its abrasive nature and variable hardness. The HPT cone crusher’s optimized design ensures high productivity and minimal downtime, making it an ideal choice for such demanding operations.

Key Features of the HPT Cone Crusher

The HPT cone crusher incorporates several innovative features that enhance performance in andesite crushing. Its multi-cylinder hydraulic system provides superior crushing force while ensuring smooth operation under fluctuating loads. The crusher’s laminated crushing principle minimizes wear on critical components, extending service life significantly. Additionally, the automated control system allows real-time adjustments to optimize output size and throughput. These features collectively contribute to higher efficiency compared to conventional cone crushers in similar applications.

Optimizing Crushing Efficiency

To maximize productivity in a 180 TPH andesite crushing plant, proper configuration of the HPT cone crusher is essential. Selecting the appropriate chamber type—standard or short-head—depends on the desired final product size. Fine-tuning parameters such as eccentric speed and closed-side setting ensures optimal particle shape with minimal fines generation. Regular monitoring of wear parts like mantles and concaves helps maintain consistent performance while reducing unexpected breakdowns. Operators should also ensure proper feed distribution to prevent uneven wear or overload conditions that could affect output quality.

Maintenance Best Practices

Maintaining an HPT cone crusher requires adherence to structured maintenance routines tailored for abrasive materials like andesite. Daily inspections should focus on hydraulic system pressure checks, lubrication levels, and abnormal vibrations during operation. Scheduled replacements of wear-resistant liners prevent sudden failures that disrupt production schedules further down the line—especially important when targeting continuous operation at full capacity (180 TPH). Using high-quality replacement parts from reputable suppliers ensures longevity without compromising safety standards set forth by industry regulations worldwide today!

Environmental Considerations

Beyond mechanical performance metrics alone lies another critical aspect: environmental impact mitigation strategies employed alongside modern equipment installations today! Dust suppression systems integrated into feeding points reduce airborne particulate emissions significantly—a major concern when processing hard rocks indoors or near populated areas alike! Noise reduction measures such as acoustic enclosures may be necessary depending upon local regulatory requirements too; these factors must not be overlooked during planning stages either way though they might seem secondary initially perhaps?

Conclusion

In summary deploying an HPT Cone Crusher within a 180 TPH Andesite Crushing Plant offers numerous advantages ranging from enhanced energy efficiency through reduced maintenance costs over time thanks largely due its robust engineering design principles applied throughout development phases accordingly then executed flawlessly thereafter indeed! By following best practices outlined above operators can achieve both economic sustainability alongside meeting stringent environmental compliance standards effortlessly thereby ensuring long-term success stories unfold naturally sooner rather than later undoubtedly so!