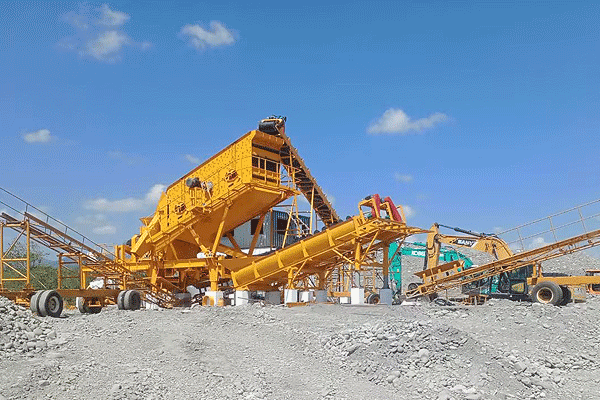

Mobile Jaw Crusher for Limestone Quarrying Plant

Introduction

Limestone quarrying is a vital industry that provides raw materials for construction, cement production, and agriculture. A mobile jaw crusher is an essential piece of equipment in modern quarrying operations, offering flexibility, efficiency, and reduced transportation costs. Unlike stationary crushers, mobile units can be relocated easily within the quarry site, optimizing material processing and minimizing downtime.

This article explores the advantages of using mobile jaw crushers in limestone quarrying plants, their operational benefits, key features to consider when selecting one, and maintenance tips to ensure longevity.

Advantages of Mobile Jaw Crushers

Mobile jaw crushers provide several benefits over traditional fixed crushing systems in limestone quarrying:

- Portability – These machines can be moved directly to the extraction site, eliminating the need for hauling raw materials over long distances.

- Versatility – They can process various sizes of limestone efficiently and are adaptable to different production requirements.

- Cost Savings – Reduced fuel consumption and lower labor costs contribute to overall operational savings.

- Quick Setup – Modern models feature hydraulic adjustments and folding conveyors for rapid deployment.

These advantages make mobile jaw crushers ideal for dynamic quarry environments where flexibility is crucial.

Key Features to Consider

When selecting a mobile jaw crusher for limestone processing, several factors should be evaluated:

- Crushing Capacity – Ensure the machine can handle the required throughput without frequent breakdowns.

- Fuel Efficiency – Advanced engines with optimized power consumption reduce operational expenses.

- Mobility Options – Track-mounted units offer better stability on uneven terrain compared to wheeled versions.

- Automation Technology – Features like remote monitoring improve efficiency by reducing manual intervention.

Investing in a well-designed unit ensures smooth operations while maximizing productivity in demanding conditions.

Maintenance Best Practices

Proper maintenance extends the lifespan of a mobile jaw crusher and prevents costly downtime:

- Regular Lubrication – Bearings and moving parts must be greased according to manufacturer guidelines to minimize wear.

- Inspection Routine – Check belts, hydraulic systems, and jaws daily for signs of damage or excessive wear.

- Cleaning Procedures – Removing dust buildup prevents overheating and ensures optimal airflow around critical components.

- Timely Replacement of Wear Parts – Jaws, liners, and screens degrade over time; replacing them proactively avoids unexpected failures.

Following these practices helps maintain peak performance while reducing repair costs significantly over time.

Conclusion

Mobile jaw crushers revolutionize limestone quarrying by combining mobility with high-efficiency crushing capabilities—making them indispensable in modern mining operations where adaptability matters most—from reducing logistical challenges through onsite processing all way down ensuring sustainable resource utilization via minimized waste generation during extraction phases alike!