Wheel Mobile Crusher Plant for River Pebble: A Comprehensive Guide

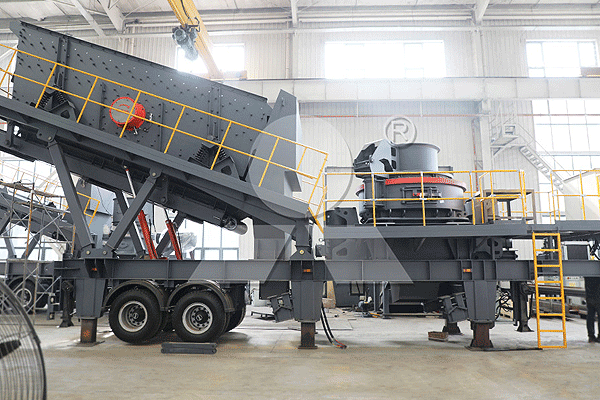

Introduction to Wheel Mobile Crusher Plants

Wheel mobile crusher plants are versatile crushing units designed for efficient material processing. Unlike stationary crushers, these units feature mobility, allowing them to be transported easily between job sites. They are particularly useful for processing river pebbles—a naturally rounded, hard-wearing aggregate commonly used in construction and landscaping.

The primary advantage of wheel-mounted crushers is their ability to operate in remote locations where fixed installations are impractical. With features like hydraulic adjustment and automated controls, they offer flexibility while maintaining high productivity. Their compact design also minimizes environmental impact, making them ideal for sustainable operations near riverbanks or quarries.

Benefits of Using Mobile Crushers for River Pebbles

River pebbles pose unique challenges due to their hardness and smooth surfaces, which can wear down traditional crushing equipment quickly. Wheel mobile crushers address these issues with specialized components such as high-chromium blow bars and impact-resistant liners that extend service life.

Additionally, mobile plants reduce transportation costs by processing materials on-site instead of hauling raw pebbles to distant facilities. This lowers fuel consumption and carbon emissions while improving project timelines. Operators can also adjust settings remotely to produce different aggregate sizes—from coarse gravels to fine sands—meeting diverse construction demands efficiently.

Key Features of an Effective Pebble Crushing Plant

A well-designed wheel mobile crusher plant for river pebbles should include several critical features:

- Robust Crushing Chamber: Optimized geometry ensures efficient fragmentation without excessive wear.

- Advanced Screening System: Multi-deck screens separate pebbles into uniform grades with minimal oversize waste.

- Fuel-Efficient Engine: Complies with emission standards while delivering reliable power output.

- User-Friendly Controls: Intuitive interfaces simplify operation and maintenance tasks even in harsh conditions.

These elements ensure consistent performance while reducing downtime caused by mechanical failures or operational errors—key factors when handling abrasive materials like river pebbles over long periods.

Environmental Considerations During Operation

Processing river pebbles requires careful environmental planning since extraction activities may disrupt aquatic ecosystems if not managed properly:

- Water Protection Measures: Implement silt fences or sedimentation ponds near waterways to prevent runoff contamination during crushing operations;

- Noise Reduction Strategies: Enclosed cabins and sound-dampening technologies minimize disturbances affecting nearby wildlife habitats;

- Dust Suppression Systems: Water sprays or misting nozzles control airborne particles generated during material handling processes effectively without compromising visibility around worksites significantly .

By integrating these practices into daily workflows , operators demonstrate commitment towards responsible resource management — enhancing both regulatory compliance & community relations simultaneously .