1000t/h Sand & Gravel Crushing Plant for Hydropower Station

Introduction

A 1000t/h sand and gravel crushing plant plays a crucial role in hydropower station construction. Such facilities provide high-quality aggregates for concrete production, dam building, and other structural requirements. Given the massive scale of hydropower projects, efficient material processing is essential to ensure timely project completion and structural integrity. This article explores the key aspects of designing and operating a large-capacity crushing plant tailored for hydropower applications.

Plant Design Considerations

Designing a 1000t/h sand and gravel crushing plant requires careful planning to meet the demands of hydropower construction. Key factors include:

- Material Characteristics: The hardness, abrasiveness, and moisture content of raw materials influence equipment selection.

- Production Capacity: A multi-stage crushing system (primary, secondary, tertiary) ensures consistent output while minimizing wear.

- Space Constraints: Compact layouts with optimized conveyor systems improve efficiency in limited areas.

- Environmental Compliance: Dust suppression and noise reduction measures must be integrated to meet regulatory standards.

Crushing Equipment Selection

The choice of machinery directly impacts productivity and operational costs. Common equipment includes:

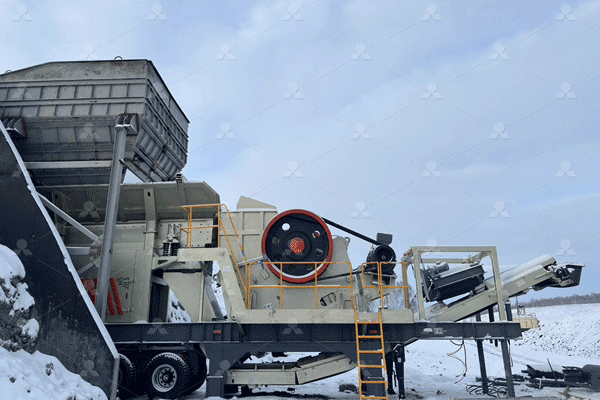

- Jaw Crushers: Ideal for primary crushing due to high capacity and reliability.

- Cone Crushers: Used in secondary stages for finer particle size reduction.

- Vertical Shaft Impact (VSI) Crushers: Produce well-shaped sand for concrete mixes.

- Screening Systems: Vibrating screens classify materials into different grades for specific applications.

Advanced automation can enhance efficiency by adjusting settings based on real-time material flow data.

Material Handling & Storage

Efficient material handling minimizes downtime and ensures continuous production:

- Feeders & Conveyors: Robust belt conveyors transport raw materials between crushing stages without bottlenecks.

- Stockpiling Systems: Radial stackers or telescopic conveyors help manage large volumes of processed aggregates.

- Moisture Control: Covered storage areas prevent material degradation due to rain or excessive humidity.

Automated weighing systems track production rates, ensuring accurate inventory management.

Quality Control & Testing

High-quality aggregates are critical for hydropower infrastructure durability:

- Gradation Analysis: Sieve tests verify particle size distribution compliance with project specifications.

- Shape & Texture Assessment: Flakiness and elongation tests ensure optimal concrete workability and strength.

- Durability Testing: Resistance to abrasion and freeze-thaw cycles is evaluated for long-term performance.

On-site laboratories enable real-time adjustments to maintain consistent quality standards.

Maintenance & Operational Efficiency

To sustain high productivity, proactive maintenance is essential:

- Wear Part Monitoring: Regular inspection of crusher liners, screens, and conveyor belts prevents unexpected failures.

- Lubrication Systems: Automated greasing units reduce friction-related wear in critical components.

- Operator Training: Skilled personnel improve efficiency by identifying early signs of equipment stress or inefficiency.

Predictive maintenance tools, such as vibration analysis sensors, help schedule repairs before major breakdowns occur.

Conclusion

A well-designed 1000t/h sand and gravel crushing plant is indispensable for large-scale hydropower projects. By optimizing equipment selection, material handling, quality control, and maintenance strategies, operators can achieve reliable production while meeting stringent construction requirements. Investing in modern technology further enhances efficiency, ensuring timely project delivery without compromising on aggregate quality or environmental compliance.