Efficient Aggregate Production: A 150 TPH Mobile Crushing Solution

Introduction to Mobile Crushing Systems

Modern aggregate production demands flexibility, efficiency, and mobility. A 150-ton-per-hour (TPH) production line utilizing three combined mobile crushing plants offers an ideal solution for medium-scale operations. These systems eliminate the need for fixed infrastructure, allowing rapid deployment across multiple sites while maintaining consistent output quality. Their modular design ensures adaptability to varying feed materials and end-product specifications.

Key Components and Workflow

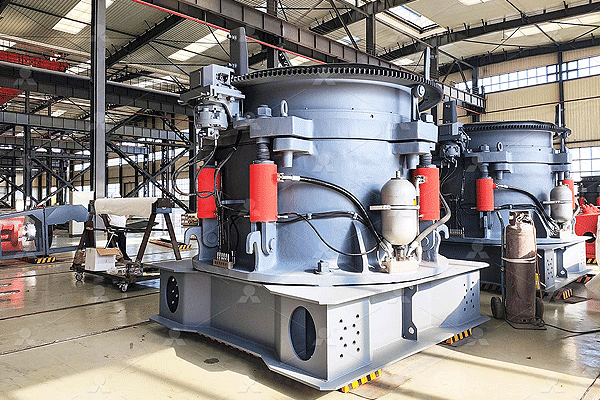

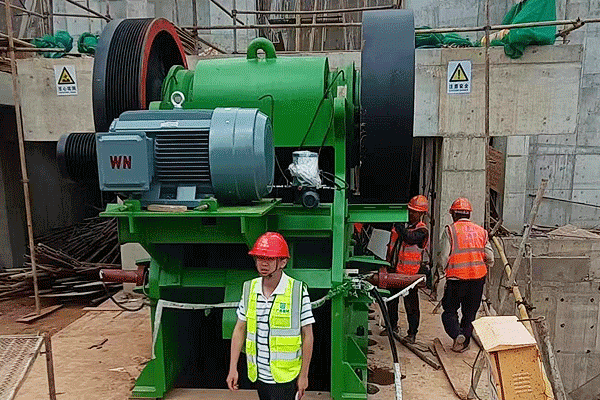

The system integrates primary crushing, secondary screening, and tertiary crushing stages across three self-contained units. The primary unit typically features a robust jaw crusher for initial size reduction, while secondary and tertiary units employ cone crushers or impactors for finer shaping. Integrated conveyors facilitate seamless material transfer between stages. Each plant operates independently yet synchronizes with others through centralized control systems, optimizing throughput without unnecessary downtime.

Advantages of Modular Mobility

Unlike stationary plants, mobile setups reduce logistical challenges significantly. Operators can relocate equipment swiftly in response to changing project demands or depleted material sources. This mobility minimizes haulage distances—lowering fuel consumption and carbon emissions—while preserving site accessibility. Additionally, compact footprints make these plants suitable for constrained spaces where traditional setups would be impractical.

Performance Optimization Strategies

To achieve consistent 150 TPH output, regular maintenance and real-time monitoring are essential. Automated feed control systems prevent crusher overloads, while adjustable screen decks ensure precise grading of final products. Operators should calibrate equipment based on material hardness variations—softer aggregates may permit higher throughput rates compared to denser rocks like granite or basalt. Telematics-enabled diagnostics further enhance uptime by predicting wear components’ replacement schedules proactively.

Environmental Considerations

Modern mobile crushing plants incorporate dust suppression systems and noise-reduction technologies to comply with environmental regulations. Enclosed conveyor belts minimize airborne particles, while hybrid power options (such as diesel-electric configurations) cut fuel usage during partial-load operations. Some models even utilize recycled water for dust control loops—reducing freshwater consumption sustainably without compromising performance standards expected from famous brands in this sector today!

Conclusion: Balancing Output With Adaptability

A well-designed 150 TPH mobile crushing line delivers both high productivity and operational versatility—critical factors in competitive markets requiring fast turnaround times between projects! By combining advanced automation with modular portability features found in contemporary designs; contractors can efficiently meet diverse client specifications while maintaining cost-effective resource utilization throughout each project lifecycle seamlessly!