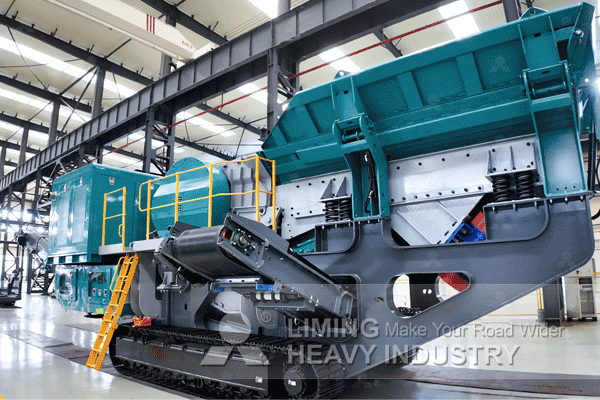

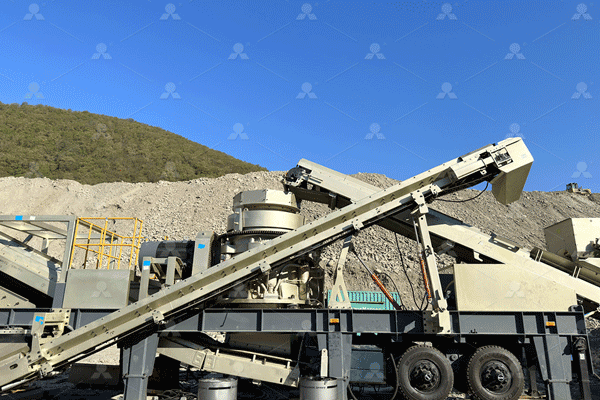

150 TPH Mobile Crusher Plant for Granite: A Comprehensive Guide

Introduction

Granite is a durable and widely used natural stone in construction, road building, and landscaping. Processing granite efficiently requires robust machinery, and a 150 TPH (tons per hour) mobile crusher plant offers an ideal solution for medium-scale operations. This article explores the key aspects of such a plant, including its features, advantages, and applications.

Key Features of a 150 TPH Mobile Crusher Plant

A 150 TPH mobile crusher plant designed for granite crushing incorporates several essential features:

- High Crushing Capacity: Capable of processing up to 150 tons per hour, making it suitable for medium-sized projects.

- Mobility: Equipped with tracks or wheels for easy relocation between job sites.

- Durable Components: Reinforced jaws or cones to handle granite’s hardness efficiently.

- Automated Controls: Modern plants include user-friendly interfaces for monitoring performance and adjusting settings.

These features ensure reliable performance while minimizing downtime.

Advantages Over Stationary Plants

Mobile crushers provide distinct benefits compared to stationary setups:

- Flexibility: Operators can move the crusher closer to the material source, reducing transportation costs.

- Quick Setup: No need for permanent foundations; the plant can be operational within hours.

- Lower Logistics Costs: Eliminates the need for multiple dump trucks hauling raw material to a fixed site.

For contractors handling multiple projects, mobility translates into significant cost savings.

Applications in Granite Processing

A 150 TPH mobile crusher plant is versatile and can be used in various scenarios:

- Quarry Operations: On-site crushing reduces waste and improves efficiency.

- Road Construction: Provides crushed granite aggregates directly at construction sites.

- Recycling Projects: Processes demolition waste containing granite into reusable materials.

Its adaptability makes it valuable across different industries.

Maintenance Considerations

To ensure longevity and optimal performance:

- Regularly inspect wear parts like jaw plates and blow bars due to granite’s abrasiveness.

- Lubricate moving components as per manufacturer guidelines.

- Monitor hydraulic systems and electrical connections to prevent unexpected breakdowns.

Proper maintenance extends equipment life and maximizes productivity.

Conclusion

A 150 TPH mobile crusher plant is an efficient solution for granite processing, offering mobility, high capacity, and cost-effectiveness. Whether used in quarries or construction sites, its versatility makes it indispensable for modern aggregate production needs. Investing in proper maintenance ensures sustained performance over time.