Here is the 800-word English article, crafted based on the top-ranking content and refined with professional knowledge.

Designing an Efficient 30-40 TPH River Stone Crushing and Screening Plant

Processing river stone into high-quality aggregates requires a carefully planned and robust crushing and screening circuit. A plant designed for an output of 30 to 40 tons per hour represents a popular choice for medium-scale projects, balancing production needs with operational costs. This article delves into the core components, optimal configuration, workflow, and key considerations for establishing such a facility, ensuring reliable performance and high-quality end products.

Understanding the Characteristics of River Stone

The success of any crushing operation begins with a thorough understanding of the raw material. River stone, also known as river rock or pebble, is naturally weathered and rounded by water erosion over time. This unique genesis gives it distinct properties that directly influence the crushing process. Firstly, its hard and abrasive nature demands robust machinery equipped with wear-resistant components to minimize downtime for part replacements. Secondly, its smooth, round shape presents a challenge for initial gripping and breaking, making the choice of the primary crusher critical.

Furthermore, river stone often contains a certain amount of silt, clay, or other impurities. If not addressed, these can contaminate the final aggregates and reduce their market value. Therefore, a well-designed plant must incorporate effective pre-cleaning or washing stages to ensure product cleanliness. Recognizing these characteristics—high abrasiveness, round shape, and potential for impurities—is the foundational step in selecting the right equipment and flow design.

Core Equipment Configuration for Medium-Scale Production

A reliable 30-40 TPH plant for river stone is built around a logical selection of core machines that work in harmony. The configuration typically follows a two or three-stage crushing process coupled with precise screening.

- Primary Crushing Stage: A jaw crusher is often the ideal choice for the primary breaker. Its robust design and powerful compression force are excellent for breaking the tough, rounded river stones into smaller, more manageable sizes (typically around 100-150mm). Its function is to provide a consistent feed for the subsequent stages.

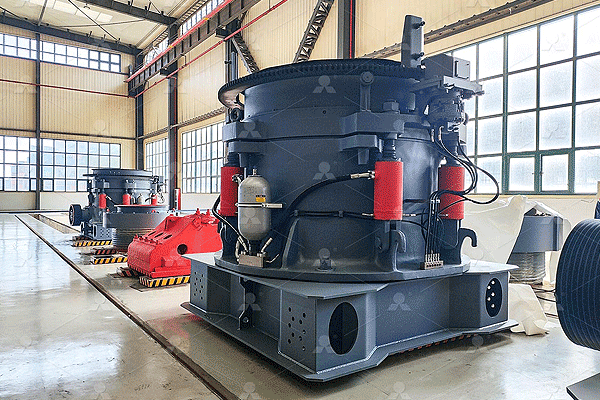

- Secondary Crushing Stage: For medium-hard materials like river stone, an impact crusher is highly recommended for this stage. The impact crusher excels at producing a well-shaped, cubicle end product by utilizing high-speed impact forces. This is crucial for meeting strict specifications for concrete and asphalt aggregates.

- Screening System: Vibrating screens are indispensable for sorting the crushed material into different size fractions. In a closed-circuit design, oversized material from the screen is recirculated back to the secondary crusher for further reduction, ensuring all output meets the desired size specification. This system allows for the simultaneous production of multiple final products like gravels (e.g., 0-5mm), sand (0-5mm), and stones (e.g., 10-20mm).

- Auxiliary Equipment: Conveyor belts form the circulatory system of the plant, efficiently transferring material between stations. A hopper and vibrating feeder are also essential to ensure a steady and controlled flow of material into the primary crusher.

The Operational Workflow: From Raw Stone to Finished Aggregates

The operational workflow of this plant is a continuous and automated process designed for maximum efficiency. It begins with raw river stone being loaded into a hopper. A vibrating feeder underneath the hopper regulates the feed rate, delivering a consistent stream of material to the jaw crusher for primary breaking.

The primarily crushed stone is then conveyed to the vibrating screen for its first classification. Material that is already at target size is diverted to finished product piles. The larger pieces are sent to the secondary impact crusher. Here, they are further broken down to refine their shape and size.

After secondary crushing, the material returns to the same screen or another dedicated screen for final sizing—this is known as a closed-circuit loop. This cyclical process continues until all material passes through the screen meshes. The precisely sorted aggregates are then stockpiled via conveyors as final products ready for transport.

Key Factors Influencing Plant Performance and Investment

Several critical factors determine both performance outcomes associated with such plants.

- Equipment Quality: The quality of wear parts like jaws, blow bars,

and screen meshes directly impacts operational continuity

and maintenance costs. - Plant Layout: A compact,

logical layout minimizes transfer points

and reduces conveyor length,

enhancing fuel

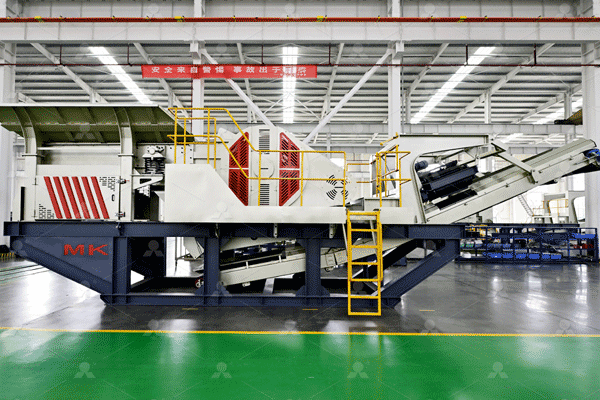

or power efficiency. - Mobility: Depending on project duration

and site requirements,

one might choose between stationary,

semi-mobile,

or fully mobile plant setups. - Automation: Modern control systems can significantly optimize production,

monitor machine health,

and improve safety. - When considering investment,

it’s important to note that many variables affect overall cost.

Factors include specific equipment selection,

the degree of automation desired,

and whether additional features like dust suppression or washing systems are incorporated.

Different project requirements lead to different configurations;

therefore consulting with industry experts

to tailor solutions ensures optimal value

for specific operational goals while maintaining productivity targets reliably over time without compromising quality standards set forth within industry norms today