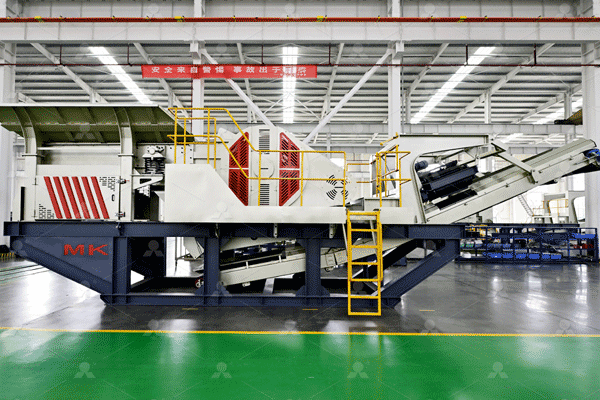

300t/h Silica Rock Portable Crushing Plant: Efficiency and Flexibility in Mining Operations

Introduction to Portable Crushing Plants

Portable crushing plants have revolutionized the mining and construction industries by offering mobility, efficiency, and cost-effectiveness. A 300t/h silica rock portable crushing plant is designed to process large quantities of raw material while maintaining flexibility in relocation. Unlike stationary plants, these units can be transported to different sites, reducing hauling costs and increasing productivity. This makes them ideal for contractors and mining operations that require frequent movement between job sites.

Key Features of a 300t/h Silica Rock Crushing Plant

A high-capacity portable crushing plant for silica rock incorporates several essential features:

- High Production Capacity: With a throughput of 300 tons per hour, it efficiently handles large-scale operations.

- Mobility: Mounted on heavy-duty trailers or crawlers, the plant can be quickly relocated.

- Durability: Built with wear-resistant materials to withstand abrasive silica rock.

- Automated Controls: Advanced systems optimize performance and reduce manual intervention.

These features ensure consistent output while minimizing operational downtime.

Advantages of Using Portable Plants for Silica Processing

Portable crushing plants offer several benefits for silica rock processing:

- Reduced Transportation Costs: Processing material on-site eliminates the need to transport raw rock to distant facilities.

- Quick Setup Time: Modular designs allow rapid deployment, enabling faster project completion.

- Environmental Benefits: On-site crushing reduces dust and emissions associated with hauling materials over long distances.

- Versatility: Suitable for various applications, including road construction, concrete production, and mining operations.

Challenges and Solutions in Silica Rock Crushing

Despite their advantages, portable crushing plants face challenges when processing silica rock:

- Abrasive Wear: Silica’s hardness accelerates equipment wear. Using high-quality liners and regular maintenance can mitigate this issue.

- Dust Control: Silica dust poses health risks; modern plants integrate water spray systems or dust suppression technologies to comply with safety regulations.

- Power Requirements: High-capacity plants demand robust power sources; diesel-electric hybrid options provide flexibility in remote locations.

Maintenance Tips for Optimal Performance

To ensure long-term efficiency, operators should follow these maintenance practices:

- Regularly inspect crusher jaws, cones, and screens for wear and tear.

- Lubricate moving parts as per manufacturer recommendations to prevent breakdowns.

- Monitor belt tension and alignment to avoid unexpected downtime.

- Schedule routine servicing of engines and hydraulic systems for uninterrupted operation.

Conclusion

A 300t/h silica rock portable crushing plant combines mobility with high production capacity, making it a valuable asset in mining and construction projects. Its ability to process abrasive materials efficiently while reducing logistical costs ensures profitability and sustainability in demanding environments. By addressing operational challenges through proper maintenance and advanced technology, businesses can maximize productivity while adhering to safety standards.