300t/h Tunnel Spoil Crushing Plant for Hydropower Station

Introduction to Tunnel Spoil Crushing

Tunnel spoil, the excavated material from tunneling operations, often contains rocks, soil, and debris. In hydropower projects, efficient processing of this material is crucial for environmental and economic reasons. A 300t/h crushing plant is designed to handle large volumes of tunnel spoil, transforming it into reusable aggregates for construction or disposal. This system ensures minimal waste while supporting sustainable project development.

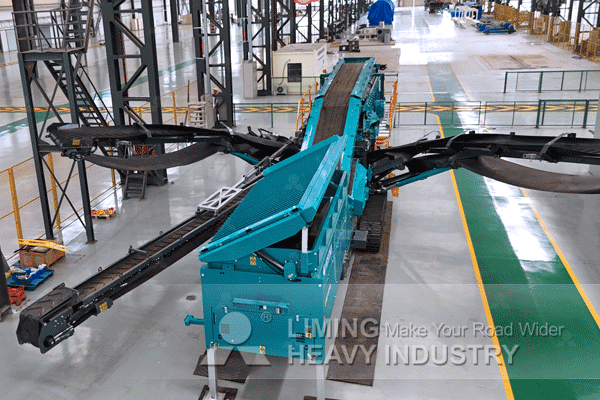

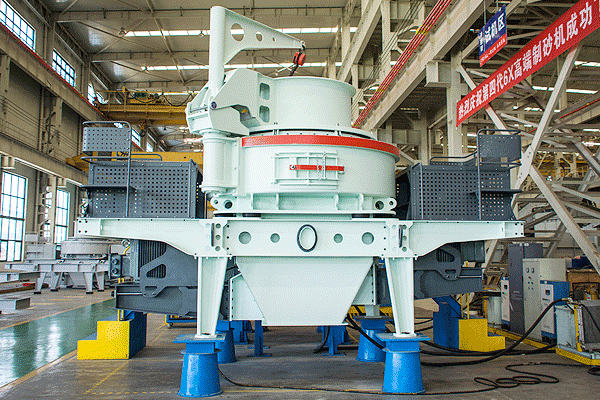

Key Components of the Crushing Plant

A 300t/h crushing plant typically includes primary and secondary crushers, vibrating screens, conveyors, and dust suppression systems. Primary crushers reduce large rocks to manageable sizes, while secondary crushers further refine the material. Screens separate different aggregate grades, and conveyors transport processed materials efficiently. Dust control mechanisms ensure compliance with environmental regulations.

Applications in Hydropower Projects

Processed tunnel spoil can be repurposed as backfill, road base, or concrete aggregates in hydropower construction. By recycling this material, projects reduce landfill dependency and lower transportation costs. Additionally, using onsite spoil minimizes the need for external raw materials, enhancing cost-efficiency and sustainability.

Technical Advantages of a 300t/h Capacity

A 300-ton-per-hour capacity balances high throughput with operational flexibility. This output suits medium to large hydropower projects where continuous spoil generation occurs. Advanced automation ensures consistent performance with minimal manual intervention, reducing downtime and labor costs. Modular designs allow for quick relocation if project requirements change.

Environmental and Safety Considerations

Modern crushing plants incorporate noise reduction and dust suppression technologies to mitigate environmental impact. Water sprays and enclosed systems control particulate emissions, while soundproofing materials reduce operational noise. Safety features like emergency stops and protective guards ensure worker protection during high-volume processing.

Conclusion: Enhancing Efficiency in Hydropower Construction

A 300t/h tunnel spoil crushing plant optimizes material management in hydropower projects by converting waste into valuable resources. Its high capacity, automation, and eco-friendly features make it an essential component for sustainable infrastructure development. Investing in such systems ensures compliance with environmental standards while improving project timelines and cost-effectiveness.