Title: The Essential 40-60 TPH Stone Crushing Plant: Efficiency Meets Affordability

Industry Background

The demand for crushed stone is strong. It is driven by global construction and infrastructure development. Markets need reliable, medium-capacity crushing solutions. The 40-60 TPH (tonnes per hour) plant is a key player. It perfectly balances output with operational cost. This capacity suits small to medium-sized projects. It meets the need for efficiency and quick setup.

Product and Technology

A typical 40-60 TPH crushing plant is a complete system. It includes several key machines working together.

- Primary Crushing: A Jaw Crusher is commonly used. It handles large, raw feed material. It provides the first reduction in size.

- Secondary Crushing: An Impact Crusher or Cone Crusher follows. It further breaks down the stone. It creates a more uniform product shape.

- Screening: A Vibrating Screen separates crushed material by size. Oversized material is sent back for re-crushing. This ensures precise final product sizing.

- Conveying: Belt Conveyors move material between stages. They are the backbone of plant logistics.

| Component | Typical Model & Specification | Key Feature |

|---|---|---|

| Jaw Crusher | PE-500×750 | High crushing ratio, simple structure |

| Cone/Impact Crusher | PYB900 / PF-1010 | Good product shape, versatile |

| Vibrating Screen | 3YK1548 | 3-deck, high screening efficiency |

| Belt Conveyors | B500x15m ~ B500x20m | Modular, easy to install |

Key technological focuses are:

- Energy Efficiency. New motors reduce power consumption.

- Semi-Automation. PLC control systems simplify operation.

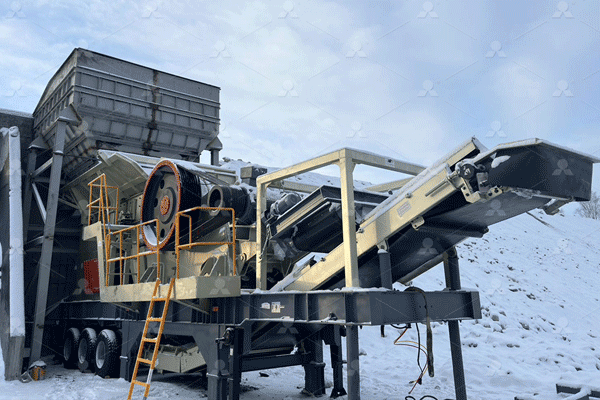

- Mobility. Some plants are wheel-mounted for easy transport.

Market Trends & Applications

The market favors compact and modular plants. The 40-60 TPH range is highly popular for its versatility.

Primary Applications:

- Aggregate Production: Producing base course, chippings, and sand for concrete.

- Road Construction: Providing stable material layers for sub-base and base courses.

- Construction Projects: Supplying materials for residential and commercial buildings.

- Railway Ballast: Producing stones of specific size and strength for railway beds.

The trend is towards integrated solutions. Plants that can produce multiple graded products simultaneously are in high demand.

Future Outlook

The future of crushing is smart and sustainable.

- Digitalization: IoT sensors will monitor machine health in real-time. This allows for predictive maintenance.

- Sustainability: Electric drives and dust suppression systems will become standard. They reduce environmental impact.

- Hybrid Power: Plants with diesel-electric hybrid options will grow. They offer fuel flexibility and lower emissions.

Frequently Asked Questions (FAQ)

-

What is the total power requirement?

The total power can range from 150 kW to 220 kW. It depends on the specific machine configuration. -

What is the typical setup time?

For a stationary plant, setup can take 1-2 weeks. A mobile plant can be ready in days. -

What kind of feed material can it process?

It can process hard rocks like granite, basalt, and river gravel. The jaw crusher’s feed size should be below 425mm. -

Do you provide after-sales service and parts?

Yes. We offer comprehensive technical support and a reliable supply of wear parts globally. -

Can the plant be customized?

Absolutely. We can customize the screen decks and crusher settings to match your target product sizes.

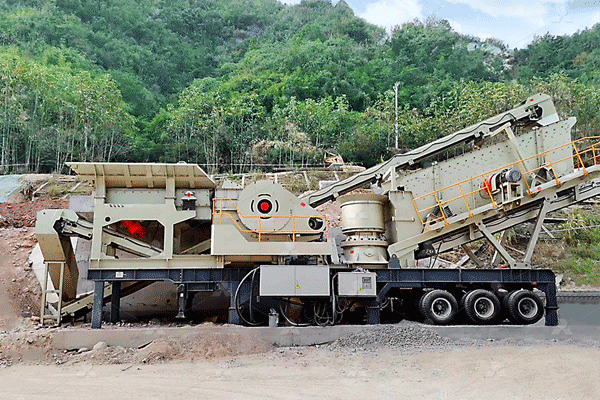

Case Study

A construction company in Southeast Asia needed to produce aggregate for a local highway project.

They chose our 40-60 TPH stationary crushing plant with a jaw crusher and an impact crusher.

The plant achieved an output of 55 TPH consistently.

It produced perfectly sized cubicle aggregates for road base.

The client praised the plant’s reliability and low maintenance costs, which helped them complete the project on schedule.

Ready to Boost Your Production?

A 40-60 TPH stone crushing plant is a smart investment for growing your business. It delivers optimal performance for medium-scale operations.

Contact us today for a free quotation. Our experts will help you design the perfect crushing solution for your specific needs