500t/h Limestone Crushing and Sand Making Plant: A Comprehensive Overview

Introduction

A 500t/h limestone crushing and sand making plant is a large-scale industrial facility designed to process raw limestone into high-quality aggregates and manufactured sand. Such plants are essential in construction, road building, and concrete production due to their efficiency and ability to meet strict material specifications. This article explores key aspects of these plants, including equipment selection, process flow, environmental considerations, and operational efficiency.

Equipment Selection

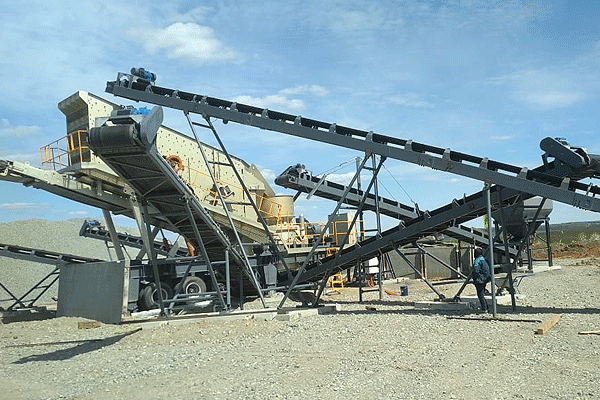

The core components of a limestone crushing and sand making plant include primary crushers, secondary crushers, vibrating screens, sand makers, and conveyors. Jaw crushers or gyratory crushers are typically used for primary crushing due to their high capacity and durability. For secondary crushing, cone crushers or impact crushers are preferred to achieve finer particle sizes. Sand makers (such as vertical shaft impactors) play a crucial role in shaping the final product into well-graded artificial sand. Selecting reliable equipment ensures stable operation and minimizes downtime.

Process Flow

The production process begins with the feeding of raw limestone into the primary crusher via a vibrating feeder. After initial crushing, the material is screened to separate oversized particles for further reduction in secondary crushers. The crushed limestone then enters sand-making machines for refinement into fine aggregates or artificial sand. Finally, vibrating screens classify the end products into different sizes before storage or transportation. Dust suppression systems are integrated at key stages to maintain air quality.

Environmental Considerations

Modern limestone processing plants prioritize sustainability by implementing dust control measures (e.g., water sprays or bag filters) and noise reduction technologies. Recycling water in washing systems minimizes waste discharge while adhering to environmental regulations. Proper site planning reduces land disturbance, and vegetation restoration is often carried out post-operation to mitigate ecological impact. Compliance with local environmental standards is mandatory for long-term operation.

Operational Efficiency

To maximize productivity, regular maintenance of machinery is essential—lubrication checks, wear-part replacements, and belt inspections prevent unexpected breakdowns. Automated control systems optimize energy consumption by adjusting equipment loads based on real-time demand. Skilled operators monitor production parameters (e.g., feed size, moisture content) to ensure consistent output quality while reducing operational costs per ton of processed material.

Conclusion

A well-designed 500t/h limestone crushing and sand making plant combines advanced machinery with efficient processes to deliver high-quality aggregates sustainably. By focusing on equipment reliability, environmental compliance, and operational best practices, such facilities can meet growing market demands while minimizing ecological footprints—a critical balance in today’s construction industry.