7 Key Differences Between Jaw Crusher and Impact Crusher

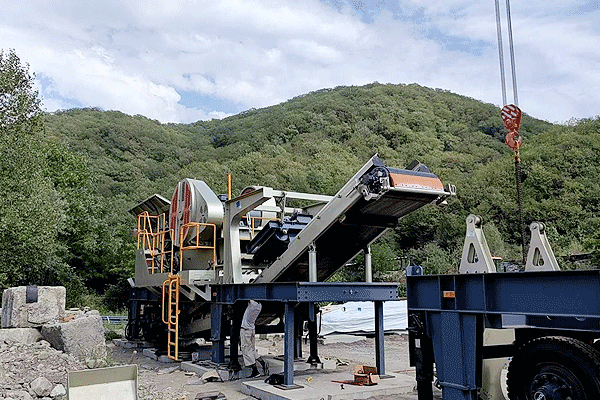

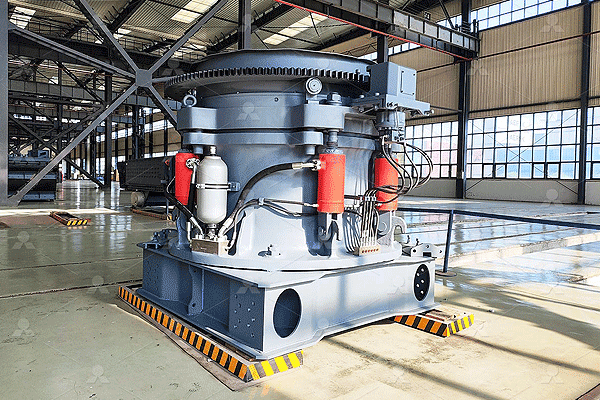

Crushing equipment plays a crucial role in mining, construction, and recycling industries. Among the most commonly used machines are jaw crushers and impact crushers. While both serve similar purposes—reducing large rocks into smaller particles—they operate differently and excel in distinct applications. Below are seven fundamental differences between these two types of crushers.

1. Crushing Mechanism

The primary distinction lies in their crushing methods. A jaw crusher applies compressive force to break materials between two rigid plates—one stationary and one moving. In contrast, an impact crusher uses rapid collisions between hammers/blow bars and the material to achieve fragmentation. This difference makes jaw crushers better suited for hard, abrasive materials, while impact crushers excel at softer or medium-hard substances.

2. Particle Shape Output

Jaw crushers produce more angular and irregularly shaped particles due to the compression-based crushing process. Impact crushers, however, generate a more cubical and uniform product because of their high-speed impact action, making them preferable when shape consistency is essential (e.g., concrete aggregate production).

3. Energy Efficiency

Jaw crushers generally consume less energy when processing hard materials since compression crushing is inherently efficient for dense rocks. Impact crushers require higher energy input due to their reliance on velocity-driven impacts but perform efficiently with softer or less abrasive materials where repeated collisions are effective.

4. Maintenance Requirements

Maintenance needs vary significantly between the two machines. Jaw crushers have fewer wear parts (primarily the fixed and movable jaws), reducing replacement frequency but requiring periodic lubrication checks. Impact crushers contain multiple wear components (hammers, blow bars, aprons), leading to higher maintenance demands but easier part replacements due to modular designs in many models from famous brands.

5. Noise and Dust Generation

Impact crushers tend to generate more noise and dust compared to jaw crushers because of their high-speed rotating mechanisms striking materials repeatedly. Proper dust suppression systems or enclosures may be necessary for compliance with environmental regulations when using impact crushers in urban or noise-sensitive areas.