800TPH Granite Crushing Plant: Efficiency and Performance

Introduction to High-Capacity Granite Crushing

Granite is one of the most durable and widely used construction materials, requiring robust crushing solutions for large-scale projects. An 800-ton-per-hour (TPH) granite crushing plant is designed to handle massive production demands while maintaining efficiency and reliability. Such plants are commonly used in mining, road construction, and infrastructure development, where high throughput and consistent output are critical.

This article explores the key components, operational benefits, and maintenance considerations of an 800TPH granite crushing plant, providing insights into optimizing performance for long-term success.

Key Components of an 800TPH Crushing Plant

An efficient granite crushing plant consists of several essential components working in harmony:

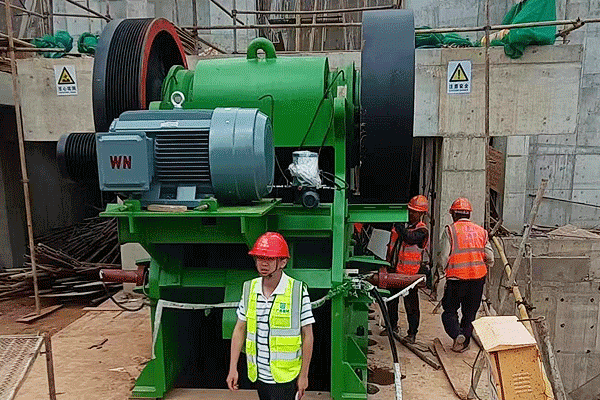

- Primary Jaw Crusher – Handles the initial size reduction, breaking large granite blocks into manageable pieces.

- Secondary Cone Crusher – Further refines the material to intermediate sizes for better shaping and gradation.

- Tertiary Impact Crusher (Optional) – Used when finer aggregates or cubical-shaped products are required.

- Vibrating Screens – Segregate crushed material into different sizes for specific applications.

- Conveyor Systems – Transport material between stages seamlessly, minimizing downtime.

- Dust Suppression Units – Ensure compliance with environmental regulations by controlling particulate emissions.

Each component must be precisely selected to match production requirements while ensuring durability under heavy loads.

Operational Advantages of an 800TPH Plant

An 800TPH granite crushing plant offers significant operational benefits:

- High Productivity – Capable of processing large volumes quickly, making it ideal for time-sensitive projects.

- Energy Efficiency – Modern crushers incorporate advanced technologies to reduce power consumption without compromising output.

- Automation Integration – Automated controls optimize performance by adjusting settings in real-time based on feed material variations.

- Versatility in Output – Adjustable crusher settings allow the production of different aggregate sizes for various applications (e.g., concrete, asphalt, railway ballast).

These advantages make high-capacity crushing plants a preferred choice for contractors handling large-scale projects with tight deadlines.

Maintenance Best Practices for Longevity

To maximize uptime and extend equipment lifespan, regular maintenance is crucial:

- Lubrication Checks – Ensure crusher bearings and moving parts are properly lubricated to prevent wear.

- Wear Parts Inspection – Monitor jaw plates, cone liners, and blow bars for signs of excessive wear and replace them promptly.

- Belt Tension Adjustment – Loose conveyor belts can cause slippage or misalignment, leading to inefficiencies or breakdowns.

- Dust Control System Maintenance – Clean filters and nozzles regularly to maintain effective dust suppression.

Scheduled downtime for preventive maintenance reduces unexpected failures and keeps production running smoothly.

Conclusion: Optimizing Granite Crushing Efficiency

An 800TPH granite crushing plant is a powerful solution for high-volume aggregate production when properly configured and maintained. By selecting the right equipment, leveraging automation, and adhering to strict maintenance protocols, operators can achieve consistent performance while minimizing operational costs. Whether supplying materials for infrastructure or commercial construction, such plants play a vital role in meeting modern industry demands efficiently and sustainably.