A tracked mobile crusher plant is an essential piece of equipment for modern crushing operations, especially when working with hard materials like granite. The versatility and mobility of these plants make them an excellent choice for both large and small-scale projects, offering high efficiency and low operational costs.

If you’re considering purchasing or renting a tracked mobile crusher plant for granite, here’s an overview of the costs involved and factors that influence the price.

What is a Tracked Mobile Crusher Plant?

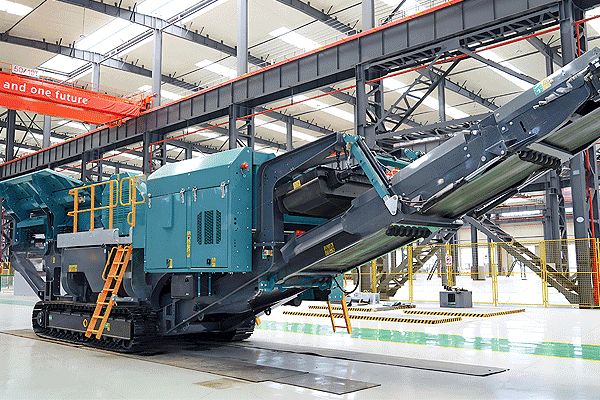

A tracked mobile crusher plant is a type of portable crushing plant that is mounted on tracks, allowing it to move easily on a variety of terrains. These plants are widely used for crushing and screening aggregates, particularly in mining and construction industries. The ability to crush granite, one of the hardest materials, requires a robust and durable crusher.

Granite crushing typically requires crushers that can handle hard, abrasive rocks, and tracked mobile plants are designed to deliver high efficiency and ease of mobility for on-site operations.

Key Features of a Tracked Mobile Crusher Plant for Granite

1. High Crushing Capacity: A 200 tph (tons per hour) mobile crusher plant is capable of processing large quantities of granite with high efficiency.

2. Advanced Technology: Modern crushers come with advanced features like hydraulic lifting, adjustable jaw settings, and integrated screening systems, allowing for better control over the size and quality of the output.

3. Mobility: The tracked design allows for easy transport across job sites, reducing downtime associated with setup and relocation.

4. Fuel Efficiency: Many modern tracked mobile crushers are designed to be more fuel-efficient, reducing operating costs in the long term.

Factors Affecting the Cost of a Tracked Mobile Crusher Plant for Granite

The price of a tracked mobile crusher plant for granite with a 200 tph capacity can vary significantly based on several factors:

1. Brand and Manufacturer:

Famous brands are typically more expensive but offer advanced features, high reliability, and long-term durability.

Chinese or Regional Brands may offer more affordable options with comparable performance, though they may not have the same level of after-sales service or long-term reliability.

2. Technology and Features:

Mobile crushers equipped with advanced technology such as automation systems, intelligent controls, and energy-efficient designs generally come at a higher price.

Models that integrate secondary and tertiary crushers, as well as screening units, may also increase the overall cost due to their added functionality.

3. Size and Configuration:

A larger mobile crusher plant with a 200 tph capacity typically costs more than smaller models. The configuration of the plant (e.g., single-stage vs. multi-stage crushing) also impacts the price.

4. Additional Features:

Crushers with features like dust suppression systems, extra-heavy duty components, or specialized granite crushing technology may command a premium price.

5. Customization and After-Sales Service:

Customization options such as specific conveyor designs or crusher configurations for unique site requirements can add to the cost.

Warranty and after-sales services, such as maintenance packages, parts availability, and customer support, also contribute to the price.

6. Location and Shipping Costs:

If you’re purchasing the crusher plant from a foreign manufacturer, shipping and import duties can significantly increase the overall cost.

Local suppliers may offer more competitive prices, but it depends on your location and the brand of the crusher.

Price Range for a 200 TPH Tracked Mobile Crusher Plant for Granite

Based on the above factors, the price of a tracked mobile crusher plant for granite with a 200 tph capacity typically falls within the following ranges:

1. Entry-Level Models:

Price Range: $150,000 – $250,000

These are typically less expensive models from regional brands, with basic features and lower durability.

2. Mid-Range Models:

Price Range: $250,000 – $450,000

Mid-range models from famous brands offer more advanced features, better build quality, and improved fuel efficiency.

3. High-End Models:

Price Range: $450,000 – $600,000+

High-end models from famous brands feature cutting-edge technology, automation, and high performance, making them ideal for larger-scale operations where downtime is critical.

Cost of Ownership and Operation

In addition to the initial purchase price, it’s important to consider the ongoing costs associated with owning and operating a tracked mobile crusher plant for granite:

1. Fuel Costs: Mobile crushers are heavy machines, and fuel can be a significant cost factor. Efficient models with energy-saving features can help reduce this cost.

2. Maintenance and Repairs: Like any machinery, regular maintenance and occasional repairs will be required. Premium models typically have lower maintenance costs over time.

3. Spare Parts: Ensure that spare parts are readily available. Some manufacturers offer excellent after-sales support, while others may have longer lead times for parts.

4. Labor Costs: If you need skilled operators for the plant, labor costs will also need to be factored into the overall cost.

Conclusion

The cost of a tracked mobile crusher plant for granite with a 200 tph capacity can vary widely, ranging from $150,000 to over $600,000, depending on the brand, features, and specifications. It’s essential to consider not only the upfront cost but also the long-term operational and maintenance costs when making your purchasing decision.

Make sure to choose a model that fits your project needs, offers the required features, and provides a good balance of performance and cost-efficiency. Consulting with suppliers and manufacturers will help you find the best machine for your specific requirements and budget.