River Rock Crusher Price in Uganda: A Comprehensive Guide

River rock crushers are essential equipment for construction, landscaping, and mining industries in Uganda. They help break down large rocks into smaller, usable aggregates for various applications. If you’re considering purchasing one, understanding the factors influencing pricing is crucial. This guide explores key aspects affecting river rock crusher prices in Uganda without referencing specific brands or companies.

—

1. Types of River Rock Crushers Available

Several types of rock crushers are commonly used in Uganda, each suited for different tasks:

- Jaw Crushers: Ideal for primary crushing, these machines handle large rocks efficiently. Prices vary based on size and capacity.

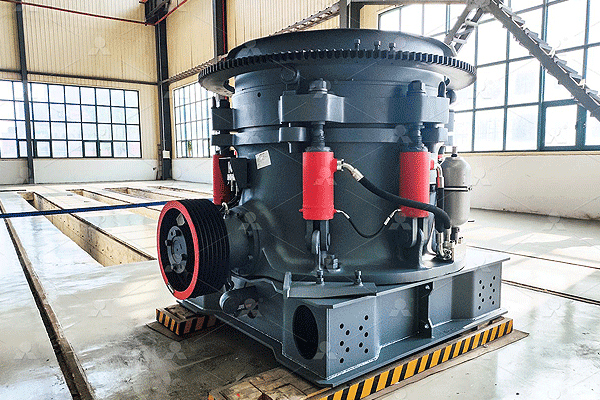

- Cone Crushers: Best suited for secondary crushing, producing finer aggregates. They tend to be more expensive due to their precision engineering.

- Impact Crushers: Suitable for softer rocks, offering versatility but may wear faster with hard river stones.

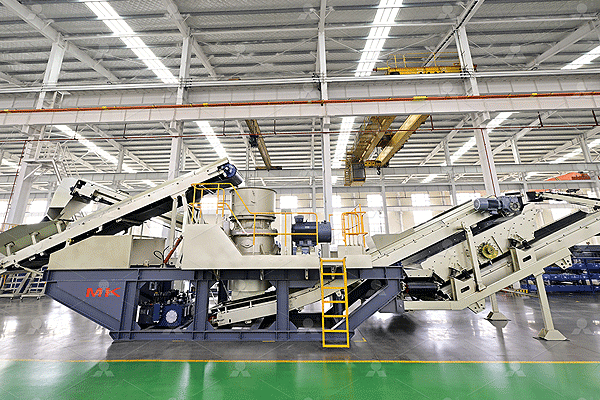

- Mobile Crushers: Portable units that reduce transportation costs but come at a premium price due to added mobility features.

- Production Capacity: Higher-capacity machines command higher prices but offer long-term savings through efficiency.

- Material Durability: Crushers built with high-grade steel last longer but are costlier upfront compared to cheaper alternatives prone to wear and tear.

- Energy Consumption: Fuel-efficient models reduce operational expenses but may have a steeper initial price tag.

- Automation Features: Advanced controls (e.g., remote monitoring) increase convenience but also raise costs significantly compared to manual systems.

The choice depends on project requirements—smaller operations may opt for cheaper stationary models, while large-scale projects might invest in mobile units despite higher upfront costs.

—

2. Key Factors Affecting Pricing

Several elements determine how much a river rock crusher costs in Uganda:

Buyers should balance immediate budget constraints with long-term operational needs when selecting equipment within their price range—opting solely based on low cost could lead to frequent breakdowns and costly downtime later on!

—

3 .Market Trends & Economic Influences

Economic conditions play a significant role in determining pricing trends within Uganda’s construction sector:

– Currency Fluctuations & Import Costs

Since many crushers are imported into Uganda from foreign manufacturers (especially China or Europe), exchange rate volatility directly impacts final retail pricing—a weaker Ugandan shilling makes imports more expensive over time! Buyers must monitor forex trends before making purchases during unstable periods where possible delays could further inflate shipment fees due to logistical bottlenecks like port congestion too…

– Local Demand Surges

During peak construction seasons (typically dry months), demand spikes often lead suppliers increasing markups temporarily until supply catches up again—procuring off-season might yield better deals if storage isn’t an issue beforehand…

– Government Policies & Taxes

Import duties levied by Ugandan authorities add substantial overheads onto machinery costs; some dealers absorb these fees partially whereas others pass them fully onto customers instead—always confirm whether quoted figures include all applicable taxes beforehand!

—

4 .Where To Buy Reliable Equipment Within Budget?

Finding trustworthy sellers requires careful research since counterfeit/substandard products exist alongside genuine ones locally:

Authorized Dealerships vs Independent Sellers

While authorized distributors typically offer warranties plus after-sales support services (albeit at slightly elevated rates), independent vendors sometimes provide lower-priced alternatives albeit without guarantees attached—weigh risks accordingly depending upon urgency versus reliability preferences here…

Online Marketplaces Considerations

E-commerce platforms facilitate price comparisons easily nowadays though verifying seller credibility remains critical prior committing funds blindly—lookout verified buyer reviews plus return policies before proceeding further ideally…

Local Auctions & Used Equipment Options

Second-hand crushers present affordable alternatives provided inspections confirm good working condition first—factor potential repair/maintenance expenses into total ownership calculations realistically though because older models usually require frequent servicing eventually regardless…

—

5 .Maintenance Costs & Long-Term Value Retention

Owning any heavy machinery involves ongoing upkeep expenditures beyond mere acquisition alone:

Regular servicing extends lifespan dramatically while minimizing unexpected breakdowns mid-project; common maintenance tasks include lubrication checks/replacements plus worn-part replacements periodically…

Spare part availability varies across regions meaning rural-based operators face longer wait times versus urban counterparts accessing components quicker generally speaking so plan accordingly if located remotely perhaps…

Resale values depend largely upon brand reputation even when avoiding naming them explicitly here since well-maintained units retain worth better than neglected ones obviously enough – always keep detailed service records handy enhancing future resale prospects maximally possible…

—

Conclusion: Making An Informed Purchase Decision

Understanding what drives river rock crusher prices helps buyers avoid overspending unnecessarily while ensuring they acquire suitable machinery matching intended usage scenarios effectively ultimately… By evaluating type requirements alongside budgetary limitations carefully beforehand alongside considering secondary factors like maintenance needs etc., Ugandan businesses can secure optimal returns from investments made wisely moving forward confidently indeed!