150 TPH Jaw Crusher Price in South Africa: A Comprehensive Guide

Introduction

When it comes to purchasing a 150 TPH (tons per hour) jaw crusher in South Africa, several factors influence the final price. Buyers must consider machine specifications, operational costs, maintenance requirements, and market trends before making an investment. This article provides a detailed breakdown of pricing considerations, key features to look for, and tips for selecting the right jaw crusher for your needs.

Factors Affecting the Price of a 150 TPH Jaw Crusher

The cost of a 150 TPH jaw crusher varies depending on multiple factors:

1. Material and Build Quality – High-grade steel and durable components increase longevity but also raise the price.

2. Technology and Features – Advanced automation, hydraulic adjustments, and energy-efficient motors contribute to higher costs.

3. Brand Reputation – Well-known manufacturers often charge premium prices due to reliability and after-sales support.

4. Import Duties and Taxes – In South Africa, import fees can significantly impact the final price if the crusher is sourced internationally.

5. Local Market Demand – Prices fluctuate based on supply availability and competition among suppliers.

Buyers should balance affordability with long-term durability to ensure cost-effectiveness over time.

Key Specifications to Consider When Buying a 150 TPH Jaw Crusher

A well-informed purchase requires evaluating essential technical aspects:

- Feed Opening Size – Determines the maximum size of raw material the crusher can process efficiently.

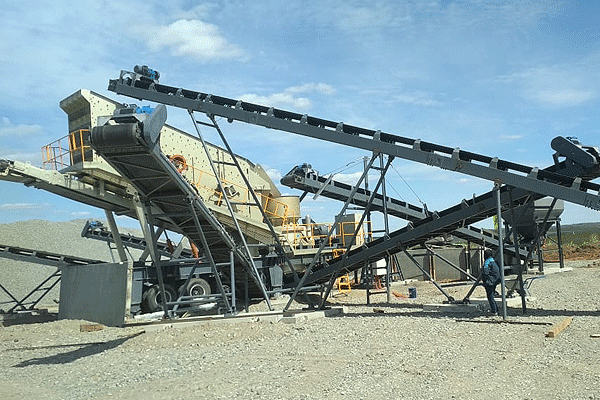

- Crushing Capacity – Ensure the machine consistently delivers 150 TPH under real working conditions.

- Power Requirements – Higher horsepower engines improve efficiency but increase operational costs.

- Adjustability Features – Hydraulic or mechanical adjustment systems allow quick setting changes for different outputs.

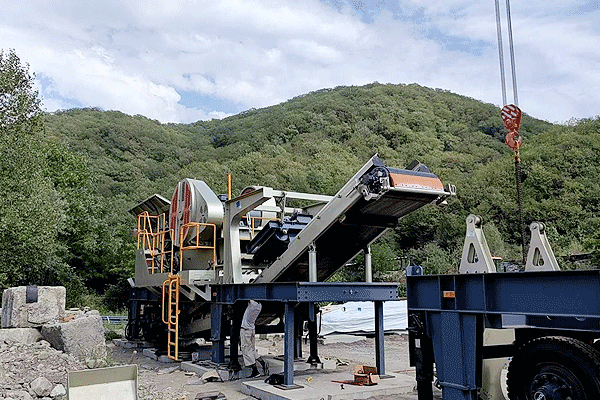

- Mobility Options – Track-mounted or wheeled designs affect portability and installation flexibility.

Selecting a model that matches your specific crushing needs prevents overspending on unnecessary features or underperforming equipment.

Operating Costs Beyond Initial Purchase Price

The upfront cost is only part of the financial commitment—operating expenses must also be considered:

1. Energy Consumption – Efficient motors reduce electricity bills but may have higher initial costs.

2. Maintenance Requirements – Regular lubrication, wear part replacements (like jaw plates), and inspections add up over time.

3. Labor Costs – Automated models reduce manpower needs compared to manual alternatives.

4. Downtime Expenses – Reliable machines minimize production halts due to breakdowns or repairs.

Investing in a robust machine with lower maintenance demands can lead to significant savings in the long run despite higher initial pricing.

Where to Buy a 150 TPH Jaw Crusher in South Africa?

South African buyers have several purchasing options:

1.Local Dealerships: Offer immediate availability,support,and warranty services but may have limited models.

2.International Suppliers: Provide competitive pricing but involve shipping delays,customs fees,and potential logistical challenges.

3.Used Equipment Markets: Lower upfront costs,but reliability risks exist unless thoroughly inspected.

4.Direct Manufacturer Purchases: Often come with better customization options but require longer lead times.

Comparing quotes from multiple sources ensures buyers secure favorable deals without compromising quality.