Crawler Mobile Crusher: A Cost-Effective Solution for 200 TPH Basalt Processing

Introduction to Crawler Mobile Crushers

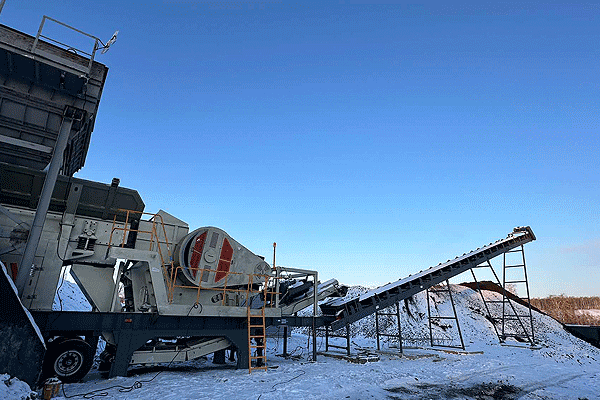

Crawler mobile crushers are versatile machines designed for efficient on-site crushing operations. Unlike stationary crushers, these units can move autonomously, making them ideal for projects requiring frequent relocation. Their tracked undercarriage ensures stability on uneven terrain, while their compact design allows them to operate in confined spaces.

For basalt processing—a hard, abrasive rock—crawler mobile crushers provide excellent durability and crushing efficiency. A 200-ton-per-hour (TPH) model is particularly suitable for medium to large-scale projects, balancing productivity and mobility. These machines reduce transportation costs by processing raw materials directly at the source, eliminating the need for hauling unprocessed rock to distant plants.

Advantages of Using a Crawler Mobile Crusher for Basalt

Basalt’s high compressive strength and abrasiveness demand robust crushing equipment. Crawler mobile crushers excel in this application due to several key benefits:

1. Mobility & Flexibility – The crawler system enables movement across rough terrain without additional transport vehicles, reducing downtime between sites.

2. High Crushing Efficiency – Equipped with powerful jaws or impactors, these crushers handle basalt efficiently while maintaining consistent output size.

3. Lower Operational Costs – On-site crushing eliminates material transport expenses, lowering overall project costs.

4. Quick Setup Time – Hydraulic systems allow rapid deployment compared to stationary plants that require foundation work.

A 200 TPH crawler mobile crusher ensures optimal throughput while maintaining fuel efficiency—a crucial factor in long-term cost savings.

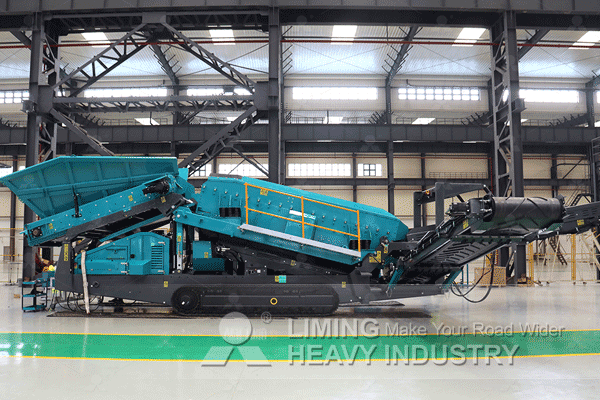

Key Features of a 200 TPH Crawler Mobile Crusher

When selecting a crawler-mounted crusher for basalt processing at 200 TPH capacity, certain features enhance performance:

- Heavy-Duty Construction – Reinforced frames and wear-resistant components extend service life under high-abrasion conditions.

- Advanced Automation – Intelligent control systems optimize crushing parameters in real-time, improving efficiency and reducing operator workload.

- Fuel-Efficient Engine – Modern models incorporate eco-friendly engines that minimize fuel consumption without sacrificing power output.

- Easy Maintenance Access – Simplified designs allow quick inspection and part replacement, reducing unplanned downtime.

These features ensure reliable operation even when processing tough materials like basalt over extended periods.

Factors Influencing Pricing of Crawler Mobile Crushers

The price of a 200 TPH crawler mobile crusher varies based on several factors:

1. Crushing Technology Used – Jaw crushers typically cost less than cone or impact models but may have different wear characteristics when handling basalt.

2. Brand Reputation & Support – Machines from famous brands often command higher prices due to proven reliability and comprehensive after-sales service networks worldwide (though specific brands are not named here).

3.Customization Requirements– Additional screening units or specialized wear parts increase upfront costs but may improve long-term ROI depending on project needs .

4.Market Demand & Availability– Regional supply chain dynamics affect pricing significantly; regions with limited availability may see higher costs .

Investors should evaluate total lifecycle expenses rather than just initial purchase price since maintenance savings often justify premium models .

Applications Beyond Basalt Crushing

While optimizedforbasal tprocessing ,a20 0TPHcrawlermobilecrus hercanhandleothermaterialssuchasgranite ,limestone,andconcrete debris.Thisversatilitymakesitanattractiveinvestmentforcontractorsworkingondiverseprojects :

-RoadConstruction–Crushedbasaltservesasanexcellentbaseaggregatefordurablepavementlayers .

-QuarryOperations–Mobileunitsallowquarriestoexpandproductionwithoutadditionalstationaryplants .

-RecyclingProjects–Someconfigurationsacceptdemolitionwaste,turningitintoreusableconstructionmaterial .

Byadjustingcrushingsettings,thesamemachinecanprocessmultiplematerialswithminimalmodifications,furtherimprovingcost-effectivenessover time .

Conclusion

Acrawlermobilecrus herwitha20 0TPHcapacityisapracticalchoiceforbasaltprocessingandbeyond.Itscombinationofmobility,efficiency,anddurabilitymakesitidealformedium-to-large-scaleprojectswherecostcontroliscritical.Investorsshouldcarefullyassessfeatures,pricingfactors,andlong-termbenefitstoselectthebestmodelfortheirspecificneeds.Withpropermaintenanceandsiteoptimization,thesemachinesdeliverconsistentperformancewhilekeepingoperationalexpenseslowovertheirservice life .