Cost Analysis of a 180 TPH Crawler Mobile Impact Crusher for Limestone

Introduction

Investing in heavy machinery like a crawler mobile impact crusher requires careful financial planning. A 180-ton-per-hour (TPH) crawler mobile impact crusher designed for limestone processing is a significant capital expenditure, but its operational benefits often justify the cost. This article breaks down the key factors influencing pricing, operational expenses, and long-term value considerations to help buyers make informed decisions.

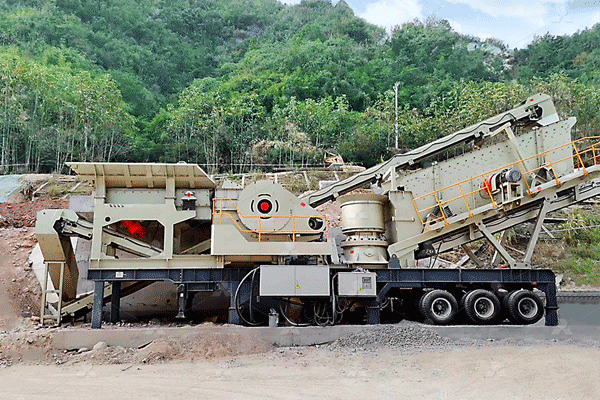

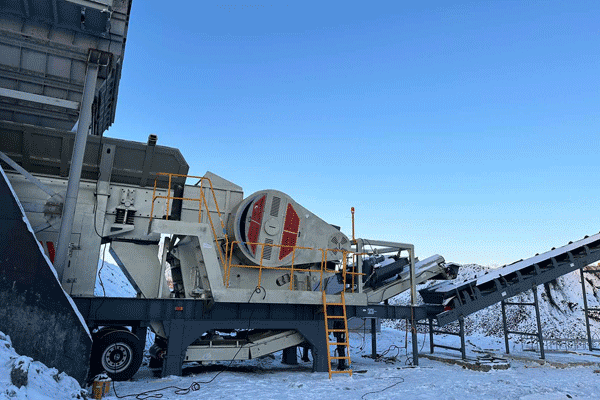

Unlike stationary crushers, crawler-mounted units offer mobility, reducing material transport costs—especially useful in quarrying or mining operations with multiple sites. However, upfront costs vary based on features like automation, engine power, and after-sales support. Below, we examine cost components and provide insights into optimizing ROI.

Key Factors Affecting Purchase Price

The price of a 180 TPH crawler mobile impact crusher depends on several variables:

- Machine Specifications – Higher throughput capacity (180 TPH vs. lower models) increases cost due to reinforced components like rotors and wear-resistant liners.

- Technology & Automation – Advanced control systems (e.g., remote monitoring) raise prices but improve efficiency and safety.

- Brand Reputation – Established manufacturers often charge premiums for reliability but may offer better resale value.

- Customization – Optional features such as dust suppression or hybrid power drives add expenses but enhance sustainability compliance.

- Market Conditions – Steel prices, tariffs, and regional demand fluctuations can impact final quotes by ±10–15%.

Prices typically range between $500,000 and $1 million USD depending on configurations. Buyers should request detailed breakdowns to compare warranties and included services (e.g., free initial maintenance).

Operational Costs Beyond Purchase

Owning a mobile crusher involves recurring expenses:

- Fuel Consumption: Diesel-powered units consume ~20–30 liters per hour under load; hybrid models reduce this but have higher upfront costs.

- Maintenance: Regular servicing (lubrication, filter changes) averages $15–$25 per operating hour; major wear parts (blow bars) may need replacement every 500–800 hours at $5,000–$10,000 per set.

- Labor: Skilled operators earn $25–$40/hour; automated systems can cut staffing needs by 30%.

- Transport & Setup: Moving between sites requires permits/low-loaders (~$2–$5 per mile).

Operational costs often total $100–$200 per hour—comparable to renting but with long-term ownership benefits like asset depreciation write-offs.

Financing Options & ROI Considerations

Few buyers pay outright; common financing methods include:

- Leasing ($8K–$15K/month): Low upfront payments but no equity buildup; ideal for short-term projects (<3 years).

- Loans (5–7% interest): Spread payments over 5 years; ownership transfers after final installment—better for stable cash flow businesses.

- Rent-to-Own: Higher monthly fees than leasing but part goes toward eventual purchase—flexible exit clauses benefit uncertain demand scenarios.