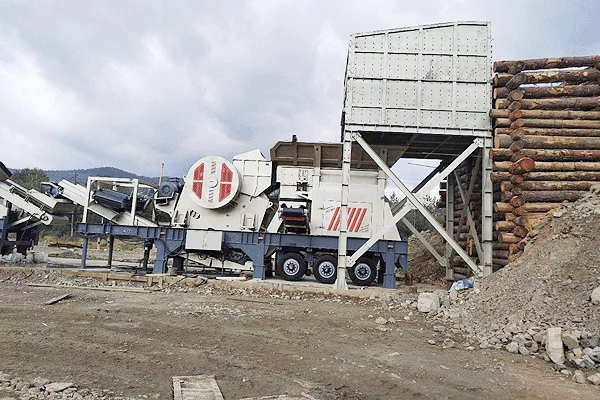

Small Mobile Crusher Plant for Granite Quarry

Introduction

Granite quarries require efficient crushing solutions to process hard stone into usable aggregates. A small mobile crusher plant offers flexibility, cost-effectiveness, and high productivity for such operations. Unlike stationary plants, mobile crushers can be easily relocated within the quarry or transported to different sites, reducing material handling costs. This article explores the benefits, components, operational considerations, and maintenance practices of small mobile crusher plants tailored for granite quarrying.

Advantages of Small Mobile Crusher Plants

Mobile crushers provide several key advantages in granite quarrying:

- Mobility – These units can move between different extraction points without requiring extensive setup time.

- Cost Efficiency – Eliminates the need for fixed infrastructure like conveyor belts and foundations.

- Compact Design – Ideal for quarries with limited space or uneven terrain where large stationary plants are impractical.

- Quick Deployment – Can be operational within hours, reducing downtime between projects.

- Environmentally Friendly – Reduced fuel consumption compared to transporting raw material to distant crushing sites.

These benefits make small mobile crushers a preferred choice for medium-sized granite quarries seeking agility without sacrificing crushing capacity.

Key Components of a Mobile Crusher Plant

A typical small mobile crusher plant consists of several critical components:

- Primary Jaw Crusher – Breaks down large granite blocks into manageable sizes (150–300 mm).

- Secondary Cone or Impact Crusher – Further reduces material to finer aggregates (20–50 mm).

- Vibrating Screen – Separates crushed granite into different size fractions for various applications (e.g., road base or concrete mix).

- Feeder System – Ensures consistent material flow into the crushers to prevent blockages and optimize efficiency.

- Hydraulic System & Power Unit – Provides mobility and operational control; some models use hybrid power options for fuel savings.

- Dust Suppression System – Minimizes airborne particles to comply with environmental regulations.

Each component plays a vital role in ensuring smooth operation while maintaining high output quality in granite processing.

Operational Considerations for Granite Crushing

Granite is highly abrasive and requires specific adjustments when using a mobile crusher:

- Crusher Settings – Adjust jaw gaps and rotor speeds based on feed size and hardness variations in granite deposits.

- Wear Parts Management – Use hardened steel or tungsten carbide liners to extend component lifespan against abrasion.

- Feed Control – Avoid oversized rocks (>80% of crusher inlet size) to prevent jamming and excessive wear on hammers/mantles.

- Dust Control Measures – Regularly spray water or use misting systems near discharge points to suppress silica dust hazards common in granite quarries.Operators should also monitor vibration levels—unusual patterns may indicate mechanical issues requiring immediate attention.Regular lubrication checksensure bearings remain functional under heavy loads typical with dense stone like granite.*Finally,*proper training minimizes human error risks during setup/troubleshooting phases.These precautions enhance both safety standards AND overall equipment longevity significantly over time!*Additionally,*automated monitoring systems help track performance metrics remotely via telematics technology available nowadays from famous brands worldwide!Such innovations streamline maintenance schedules proactively rather than reactively fixing breakdowns later down line unnecessarily wasting resources unnecessarily!***Thus optimizing uptime percentages dramatically improving return-on-investment calculations favorably long term perspective wise indeed!