Crawler-Type Mobile Jaw Crusher for Limestone: A Comprehensive Guide

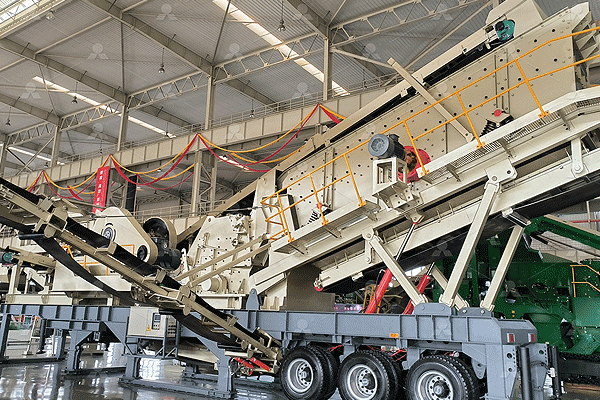

Introduction to Crawler-Type Mobile Jaw Crushers

Crawler-type mobile jaw crushers are versatile crushing machines designed for efficient processing of various materials, including limestone. Unlike stationary crushers, these units are mounted on crawler tracks, allowing them to move easily across different terrains. This mobility makes them ideal for quarrying, mining, and construction projects where frequent relocation is required.

The primary advantage of a crawler-type mobile jaw crusher is its ability to crush limestone directly at the extraction site, reducing transportation costs and improving operational efficiency. These machines feature a robust jaw crusher as the core component, capable of handling large feed sizes and producing uniform output. Additionally, their self-propelled design ensures quick setup and minimal downtime between operations.

Key Features of Crawler-Type Mobile Jaw Crushers

Crawler-type mobile jaw crushers come equipped with several advanced features that enhance performance and reliability:

- Mobility & Stability – The crawler undercarriage provides excellent traction on rough terrain while maintaining stability during crushing operations.

- High Crushing Efficiency – Equipped with powerful jaws and optimized crushing chambers, these units deliver high throughput with minimal energy consumption.

- Easy Maintenance – Modular designs allow quick access to key components such as the jaw plates, bearings, and hydraulic systems for servicing.

- Fuel Efficiency – Modern models incorporate intelligent power management systems to reduce fuel consumption without compromising performance.

- Dust & Noise Suppression – Many units include built-in dust suppression systems and noise-reducing technologies to comply with environmental regulations.

These features make crawler-type mobile jaw crushers a preferred choice for limestone processing in demanding environments.

Applications in Limestone Crushing

Limestone is a widely used material in construction, agriculture, and industrial processes due to its durability and versatility. Crawler-type mobile jaw crushers are particularly effective in processing limestone because of their ability to handle medium-hard materials efficiently. Some common applications include:

- Quarry Operations – Crushing raw limestone into aggregates for road construction or concrete production.

- Mining Projects – Processing limestone extracted from open-pit mines before further refinement or transport.

- Recycling & Demolition – Reusing crushed limestone from demolished structures as base material for new projects.

- Infrastructure Development – Supplying crushed limestone for railway ballast or foundation layers in large-scale infrastructure projects.

The flexibility of crawler-mounted units allows operators to move between different sites seamlessly, optimizing productivity across multiple applications.

Advantages Over Stationary Crushers

Compared to stationary jaw crushers, crawler-type mobile units offer several distinct benefits:

- Reduced Transportation Costs – Since the crusher can be moved directly to the material source, there’s no need for additional hauling equipment or intermediate stockpiling.

- Faster Deployment – Setup time is significantly shorter compared to fixed installations, enabling quicker project turnaround times.

- Lower Infrastructure Requirements – No permanent foundations or extensive site preparation are needed before operation begins.

- Adaptability to Changing Conditions – If mining or quarrying operations shift locations frequently, mobile crushers can follow without requiring major logistical adjustments.

These advantages make crawler-type mobile jaw crushers an economically viable solution for many limestone processing scenarios where flexibility is crucial.

Maintenance & Operational Best Practices

To maximize the lifespan and efficiency of a crawler-type mobile jaw crusher when processing limestone:

- Regular Lubrication Checks: Ensure bearings and moving parts are properly lubricated according to manufacturer guidelines.

- Monitor Wear Parts: Replace worn-out jaw plates promptly since abrasive materials like limestone accelerate wear.

- Inspect Hydraulic Systems: Leaks or pressure drops should be addressed immediately.

- Track Condition Monitoring: Check track tension regularly since uneven wear affects mobility.

- Operator Training: Proper training ensures safe operation while minimizing unnecessary strain on components.

Following these practices helps maintain peak performance while reducing unexpected breakdowns.

Future Trends in Mobile Crushing Technology

As demand grows for sustainable mining solutions,

future developments may include:

- Hybrid power options combining diesel engines with electric drives

- AI-assisted optimization systems adjusting settings automatically based on feed material

- Enhanced automation reducing manual intervention during operation

These innovations will further improve efficiency while lowering environmental impact—making crawlers even more indispensable in modern mineral processing industries including those focused on limestone extraction.

This article provides an unbiased overview without referencing specific brands—focusing solely on technical aspects relevant across industry standards today!