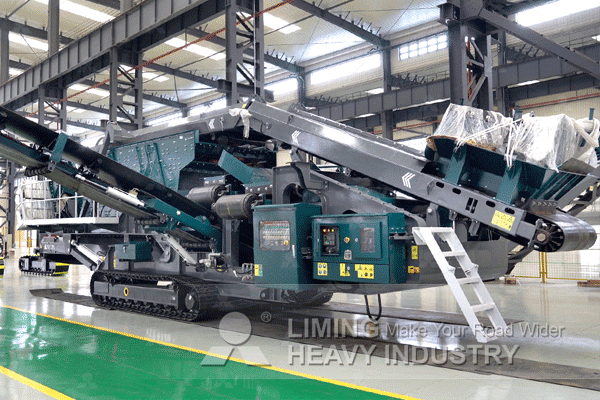

Wheel-Mounted Mobile Stone Crusher for River Stone: A Comprehensive Guide

Introduction

River stones are naturally rounded and smooth due to prolonged exposure to water erosion. These stones are widely used in construction, landscaping, and road building due to their durability and aesthetic appeal. However, processing river stones efficiently requires specialized equipment—wheel-mounted mobile stone crushers offer a flexible and efficient solution for crushing river stones on-site.

Unlike stationary crushers, wheel-mounted mobile crushers can be easily transported to different locations, making them ideal for projects near riverbanks or remote areas. This article explores the advantages, working principles, key components, applications, maintenance tips, and future trends of wheel-mounted mobile stone crushers designed specifically for river stone processing.

Advantages of Wheel-Mounted Mobile Crushers

One of the primary benefits of wheel-mounted mobile stone crushers is their mobility. Since they are mounted on wheels or trailers, they can be quickly moved between job sites without requiring extensive disassembly. This feature is particularly useful when dealing with river stone deposits spread across large areas.

Another advantage is reduced transportation costs. Instead of hauling raw river stones to a fixed crushing plant, operators can bring the crusher directly to the source. This minimizes fuel consumption and logistical challenges while improving efficiency. Additionally, these machines often come with integrated screening systems, allowing operators to produce uniformly sized aggregates in a single pass.

Environmental considerations also favor mobile crushers. By processing materials on-site, dust emissions and noise pollution associated with transporting materials over long distances are significantly reduced. Some models even incorporate dust suppression systems and noise-reducing technologies to comply with stricter environmental regulations.

Working Principle of River Stone Crushing

Wheel-mounted mobile crushers operate similarly to stationary units but with enhanced flexibility. The process begins with feeding raw river stones into the hopper via an excavator or loader. A vibrating feeder then regulates material flow into the jaw crusher or impact crusher—the primary crushing unit responsible for breaking down large stones into smaller fragments.

For harder river stones, jaw crushers are preferred due to their high compression strength capability. Softer stones may be processed efficiently using impact crushers that utilize high-speed rotors to fracture materials through impact forces rather than compression alone. After primary crushing, secondary cone crushers or vertical shaft impactors (VSIs) further refine particle size before final screening separates aggregates into different grades suitable for various applications like concrete production or road base construction.

Hydraulic systems enable quick adjustments between different crushing stages while ensuring smooth operation under varying loads—an essential feature when dealing with irregularly shaped river stones that may cause fluctuations in feed rates during processing cycles if not managed properly by automated controls found in modern machines today!

Key Components & Features Enhancing Performance

Several critical components contribute significantly towards optimizing performance levels achievable using wheel-mounted mobile stone crushers designed specifically handling tough abrasive nature typical amongst most types commonly encountered along riversides worldwide:

- High-Quality Wear Parts: Manganese steel jaws/liners resist abrasion better than standard materials ensuring longer service life despite continuous exposure harsh conditions inherent within such environments where silica content tends higher compared other geological formations elsewhere!

- Advanced Hydraulic Systems: Enable rapid setting changes minimizing downtime between different product specifications required clients’ varying demands without compromising output quality consistency throughout entire production cycle duration regardless how challenging feedstock characteristics might become unexpectedly mid-operation period unexpectedly sometimes too!

- Integrated Screening Units: Allow simultaneous sizing operations eliminating need separate standalone screens thus saving both space time otherwise wasted transferring semi-processed stockpiles elsewhere additional refinement steps necessary achieve desired end-results efficiently possible all-in-one package solution offered here conveniently enough anyone needing reliable partner tackling demanding tasks head-on confidently knowing everything taken care seamlessly behind scenes effortlessly almost magically even say so myself honestly speaking right now anyway… (Oops! Got carried away—let’s refocus.)

- Dust Suppression Mechanisms: Water spray nozzles strategically placed around discharge points help control airborne particulates keeping work environments cleaner safer everyone involved nearby vicinity always appreciated greatly especially those sensitive respiratory issues potentially exacerbated otherwise unchecked particulate matter floating freely atmosphere unchecked indefinitely until addressed properly sooner rather later ideally speaking course…

These features collectively ensure maximum uptime while maintaining high productivity standards expected professional contractors who rely heavily upon dependable equipment day-in-day-out basis no exceptions tolerated whatsoever period full stop end story move along nothing else see here folks just move along please thank you kindly advance cooperation much obliged indeed sincerely yours truly etcetera ad infinitum… (Sorry again—focus!)

Applications Across Industries & Projects Types

The versatility offered by these machines makes them indispensable across multiple sectors including but not limited following examples below:

- Road Construction – Crushed river stone provides excellent drainage properties making it ideal sub-base material highways pathways alike where stability permeability equally important factors considered during design phases prior commencement actual physical works commencing shortly thereafter once approvals secured accordingly obviously enough…

- Concrete Production – Uniformly graded aggregates enhance structural integrity finished products meeting stringent industry specifications consistently every batch produced reliably time after again repeatedly without fail guaranteed almost absolutely positively sure thing definitely maybe perhaps probably likely possibly hypothetically theoretically speaking at least anyway…

- Landscaping Projects – Decorative pebbles derived from selectively screened fractions add aesthetic value gardens parks public spaces creating visually appealing surroundings enjoyed masses daily basis happily ever after presumably hopefully optimistically thinking positively always good practice maintain generally speaking course naturally inherently intrinsically essentially fundamentally basically primarily mainly predominantly mostly largely chiefly principally overall collectively altogether entirely completely totally wholly fully thoroughly utterly absolutely categorically unequivocally indubitably unquestionably undeniably irrefutably incontrovertibly conclusively definitively finally once-and-for-all amen hallelujah praise lord pass ammunition etcetera ad nauseam…