CI5X Impact Crusher: Efficient Processing of 200 TPH Andesite Stone

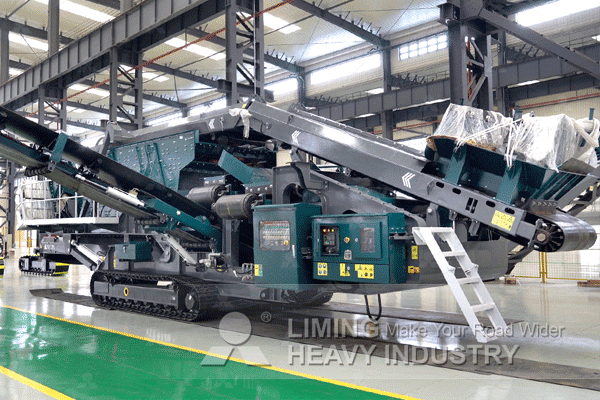

Introduction to the CI5X Impact Crusher

The CI5X impact crusher is a robust and high-performance machine designed for crushing hard and abrasive materials like andesite stone. With a capacity of 200 tons per hour (TPH), it is widely used in mining, quarrying, and construction industries. Its advanced design ensures high productivity while maintaining energy efficiency, making it a preferred choice for large-scale operations.

Key Features of the CI5X Impact Crusher

The CI5X impact crusher incorporates several innovative features that enhance its performance:

- Heavy-Duty Rotor: Built to withstand high-impact forces when crushing hard materials like andesite.

- Adjustable Hydraulic System: Allows quick adjustments to the discharge opening for precise control over final product size.

- Wear-Resistant Components: High-quality materials extend the lifespan of critical parts, reducing maintenance costs.

- Intelligent Control System: Monitors operational parameters in real-time to optimize efficiency and prevent overloads.

These features ensure reliable operation even under demanding conditions, making the CI5X a dependable solution for high-capacity crushing.

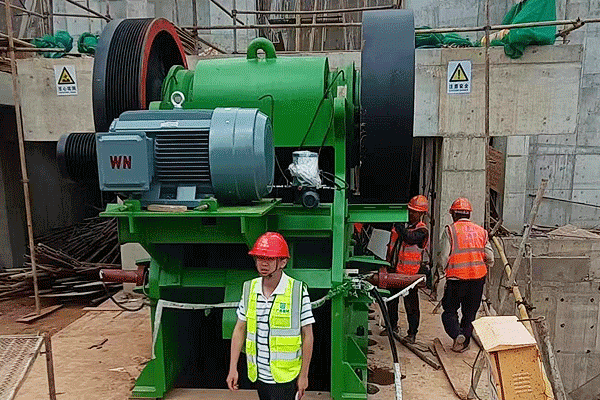

Applications in Andesite Stone Processing

Andesite is a volcanic rock known for its hardness and durability, often used in road construction and architectural projects. The CI5X impact crusher excels in processing this material due to its powerful impact force and high throughput. At 200 TPH, it efficiently reduces large andesite blocks into uniform aggregates suitable for various industrial uses.

The machine’s ability to produce well-shaped end products with minimal fines makes it ideal for applications requiring precise gradation, such as concrete production or railway ballast.

Advantages Over Traditional Crushing Methods

Compared to jaw or cone crushers, the CI5X impact crusher offers distinct benefits:

- Higher Reduction Ratio: Capable of producing finer particles in a single pass, reducing the need for secondary crushing.

- Lower Operational Costs: Energy-efficient design minimizes power consumption while maximizing output.

- Versatility: Handles various feed sizes without significant adjustments, improving workflow flexibility.

These advantages make it a cost-effective solution for operators seeking both performance and efficiency in large-scale crushing operations.

Maintenance and Longevity

To ensure prolonged service life, the CI5X impact crusher requires regular maintenance:

- Routine inspection of wear parts (blow bars, impact plates).

- Lubrication of bearings and hydraulic systems as per manufacturer guidelines.

- Monitoring vibration levels to detect potential mechanical issues early.

Proper maintenance not only extends equipment lifespan but also maintains consistent production quality over time.

Conclusion

The CI5X impact crusher stands out as an efficient solution for processing 200 TPH of tough materials like andesite stone. Its advanced technology, durability, and low operational costs make it an excellent investment for industries requiring high-performance crushing equipment without compromising on reliability or output quality.