Best Price Jaw Crusher for Gold Ore and Copper Ore Processing

Introduction

When it comes to processing hard materials like gold ore and copper ore, jaw crushers are among the most reliable and cost-effective solutions. Their robust design, high efficiency, and ability to handle abrasive materials make them indispensable in mining operations. This article explores key factors to consider when selecting a jaw crusher for gold and copper ore processing while ensuring affordability without compromising performance.

Key Features of an Efficient Jaw Crusher

A high-quality jaw crusher for gold and copper ore should possess several essential features:

- High Crushing Ratio: Ensures efficient reduction of large ore chunks into smaller, manageable sizes.

- Durable Materials: Manganese steel or hardened alloy jaws resist wear from abrasive ores.

- Adjustable Discharge Settings: Allows operators to control the final product size for downstream processes.

- Low Maintenance Design: Simplified construction reduces downtime and repair costs.

Investing in a crusher with these features ensures long-term reliability even under heavy-duty conditions.

Cost Considerations Without Sacrificing Quality

Finding the best-priced jaw crusher doesn’t mean settling for inferior quality. Here’s how to balance cost-effectiveness with performance:

- Compare Multiple Suppliers: Obtain quotes from different manufacturers to identify competitive pricing.

- Evaluate Energy Efficiency: A slightly higher upfront cost may be justified by lower operational expenses over time.

- Check Availability of Spare Parts: Ensure replacement components are affordable and readily available to avoid delays.

Avoid models that compromise critical components like bearings or structural integrity solely for lower pricing.

Applications in Gold and Copper Ore Processing

Jaw crushers play a crucial role in mineral extraction by breaking down raw ore into smaller fragments suitable for further processing:

- Primary Crushing: Handles initial size reduction before secondary grinding or leaching processes.

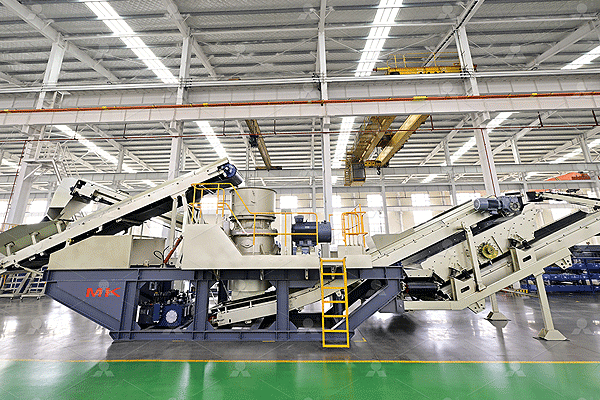

- Portable Configurations: Ideal for remote mining sites where mobility is essential.

- Scalability: Suitable for both small-scale operations and large industrial setups with modular designs.

Their versatility makes them indispensable across various stages of mineral processing plants specializing in precious metals like gold or industrial metals like copper.

Maintenance Tips for Longevity

Proper maintenance extends the lifespan of your jaw crusher while minimizing unexpected breakdowns:

- Regularly inspect wear parts (jaws, toggle plates) and replace them before excessive damage occurs.

- Lubricate bearings according to manufacturer recommendations.

- Monitor belt tension if applicable—improper alignment accelerates component wear.

- Clean debris buildup around moving parts periodically.

Following these practices ensures consistent performance while reducing long-term ownership costs significantly compared to neglected equipment requiring premature replacements.

This structured guide provides actionable insights without relying on brand-specific promotions—ensuring neutrality while delivering valuable information tailored toward buyers seeking budget-friendly yet durable solutions specifically designed around challenging materials such as gold & copper ores!