Concrete Crushing Plant Price in Russia

1. Introduction to Concrete Crushing Plants

Concrete crushing plants are essential for recycling construction waste into reusable materials. In Russia, the demand for these plants has grown due to increasing infrastructure projects and environmental regulations. These facilities break down demolished concrete into smaller aggregates, which can be reused in new construction projects. The price of a concrete crushing plant depends on factors such as capacity, technology, and regional market conditions.

2. Key Factors Affecting Prices

Several factors influence the cost of concrete crushing plants in Russia:

- Capacity: Larger plants with higher output capacities are more expensive but offer better long-term efficiency.

- Technology: Advanced automation and energy-efficient systems increase initial costs but reduce operational expenses.

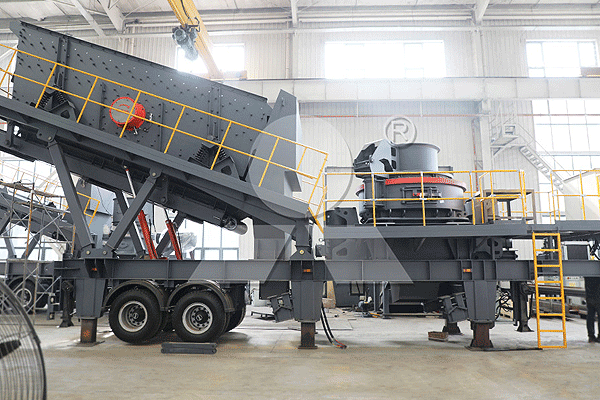

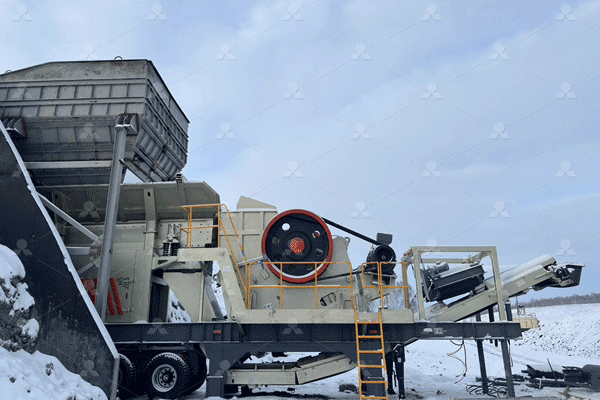

- Mobility: Stationary plants are cheaper, while mobile units cost more due to their flexibility and transportability.

- Import vs. Local Manufacturing: Imported machinery may have higher prices due to tariffs, whereas locally assembled options could be more affordable.

3. Average Price Range in Russia

The price of a concrete crushing plant in Russia varies widely based on specifications:

- Small-scale plants (50–100 tons per hour) range from $100,000 to $300,000.

- Mid-range plants (100–200 tons per hour) cost between $300,000 and $600,000.

- Large-scale installations (200+ tons per hour) can exceed $1 million.

Used or refurbished equipment is available at lower prices but may require additional maintenance costs.

4. Regional Price Variations

Prices differ across Russian regions due to logistics and local demand:

- Moscow & St. Petersburg: Higher prices due to increased demand and transportation costs for imported machinery.

- Siberia & Far East: Prices may rise due to remote locations and logistical challenges in equipment delivery.

- Southern Russia: More competitive pricing as some manufacturers operate closer to these areas, reducing shipping expenses.

5. Cost-Saving Tips for Buyers

To minimize expenses when purchasing a concrete crushing plant:

- Compare multiple suppliers before making a decision.

- Consider leasing or financing options if upfront costs are prohibitive.

- Opt for locally manufactured models to avoid import duties and long shipping times.

- Evaluate total ownership costs, including maintenance and energy consumption, rather than just the initial price tag.

6. Future Market Trends

The Russian market for concrete crushing plants is expected to grow with rising infrastructure investments and stricter waste management policies. Innovations in automation and sustainability will likely influence pricing trends, making newer models more efficient but potentially more expensive initially. Buyers should stay informed about technological advancements that could improve long-term returns on investment.

By understanding these factors, businesses can make informed decisions when investing in a concrete crushing plant in Russia while balancing cost and performance needs effectively.