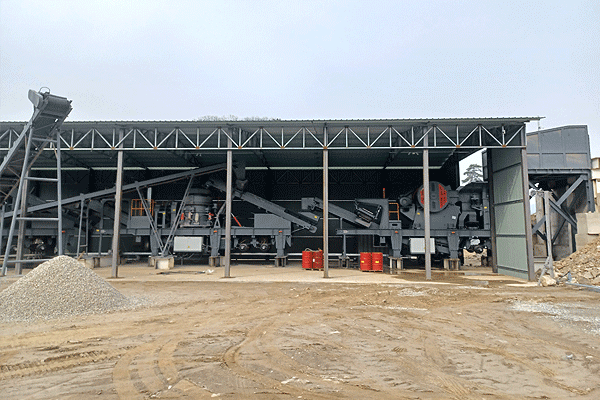

Ethiopia 100-150TPH Basalt Portable Crushing Plant

Introduction to Portable Crushing Solutions

Portable crushing plants have revolutionized the mining and construction industries by offering flexibility and efficiency. In Ethiopia, where infrastructure development is rapidly expanding, a 100-150TPH basalt portable crushing plant provides an ideal solution for processing hard and abrasive materials. Unlike stationary plants, portable units can be easily relocated, reducing transportation costs and increasing productivity in remote areas. This makes them particularly valuable for road construction, dam projects, and other large-scale developments across Ethiopia.

Key Features of the Basalt Crushing Plant

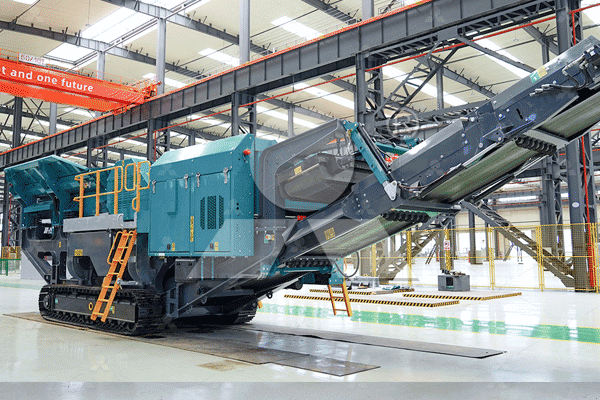

The 100-150TPH basalt portable crushing plant is designed for durability and high performance. It typically includes a primary jaw crusher for coarse crushing, a secondary cone crusher for finer output, and vibrating screens to classify materials efficiently. The entire system is mounted on wheeled or tracked chassis, allowing quick setup and dismantling. Advanced automation controls ensure smooth operation with minimal manual intervention. Additionally, dust suppression systems comply with environmental regulations while maintaining worker safety—a crucial factor in Ethiopia’s growing industrial sector.

Advantages Over Traditional Crushing Methods

Traditional stationary crushing setups require significant investment in infrastructure and logistics. In contrast, portable plants eliminate the need for fixed foundations and reduce material handling expenses since they can be moved closer to extraction sites or project locations. For Ethiopian contractors working on multiple sites simultaneously—such as highway construction or urban development—this mobility translates into faster project completion times and lower operational costs. Furthermore, modular designs allow easy upgrades or expansions based on changing demands without major downtime or additional investments in new equipment from famous brands’ suppliers overseas .

Applications Across Ethiopian Projects

Basalt’s hardness makes it ideal for producing high-quality aggregates used in concrete production , asphalt mixtures , railway ballast ,and erosion-resistant structures like riverbank reinforcements .In Ethiopia,the demand has surged due to ongoing mega-projects including hydroelectric dams,paved roads,and urban housing initiatives.A portable plant capable of processing up tp150 tons per hour ensures consistent supply chains eveninremote regions where access may be limited.This adaptability supports both government-led infrastructure programsand private sector developments equally well .

Environmental Considerations And Sustainability

Sustainability remainsakey concernwhen deploying heavy machineryin fragile ecosystems.Portablecrushingplantsaddress thisby minimizing land disturbance through compact footprintsandreduced fuel consumptioncompared tomultiple haulingtrucks transportingrawmaterials longdistances.Ethiopia’semission standardsare increasingly stringent,makingenergy-efficientmodelswithlowcarbonfootprintsmorerelevantthanever.Someunitsalsoincorporate recycledwater systemsfor dustcontrol,further reducingenvironmental impactswhile conservingresources—animportantfactorforprojects locatednearprotectedareasorcommunitiesdependentonlocalwater sources .