Trinidad and Tobago 400TPH Sand Washing and Screening Plant: A Comprehensive Overview

Introduction

The demand for high-quality construction materials in Trinidad and Tobago has led to the development of advanced sand processing facilities. A 400-ton-per-hour (TPH) sand washing and screening plant plays a crucial role in ensuring the production of clean, well-graded sand for various infrastructure projects. This facility integrates modern technology to optimize efficiency while minimizing environmental impact.

This article explores the key components, operational benefits, and sustainability aspects of such a plant, providing insights into its significance in the local construction industry.

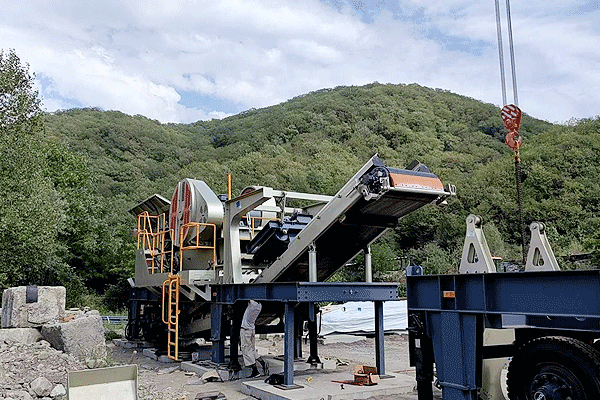

Key Components of the Plant

A 400TPH sand washing and screening plant consists of several essential components:

- Feed Hopper & Conveyor System – Ensures a steady supply of raw material to the processing unit.

- Vibrating Screen – Separates sand particles by size, removing oversized debris.

- Sand Washer – Cleans impurities such as clay, silt, and organic matter using water jets or scrubbing mechanisms.

- Dewatering Screen – Reduces moisture content before final stockpiling.

- Water Recycling System – Minimizes water consumption by filtering and reusing process water.

These components work together to produce high-quality sand suitable for concrete production, road construction, and other applications.

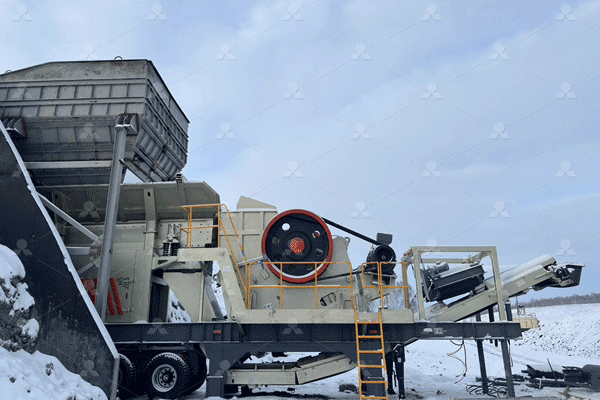

Operational Efficiency & Performance

With a capacity of 400TPH, this plant is designed for large-scale operations while maintaining energy efficiency. Automated controls allow operators to adjust settings for optimal performance based on feed material variations. Key advantages include:

- High throughput with minimal downtime due to robust machinery design.

- Reduced labor costs through automation and remote monitoring capabilities.

- Consistent output quality meeting international standards for construction-grade sand.

The plant’s modular design also allows for easy expansion if future demand increases.

Environmental Considerations

Sustainability is a priority in modern sand processing plants. The Trinidad and Tobago facility incorporates eco-friendly features such as:

- Closed-Loop Water Systems – Recycles up to 90% of process water, reducing freshwater consumption.

- Dust Suppression Technology – Minimizes airborne particles during screening and washing operations.

- Noise Reduction Measures – Soundproofing materials help comply with local environmental regulations.

By adopting these practices, the plant minimizes its ecological footprint while supporting responsible resource extraction.

Economic Impact & Industry Benefits

The establishment of a 400TPH sand washing plant contributes significantly to Trinidad and Tobago’s economy by:

- Creating employment opportunities in operations, maintenance, and logistics sectors.

- Reducing reliance on imported construction materials, lowering project costs.

- Supporting infrastructure development with locally sourced high-quality aggregates.

Additionally, consistent supply ensures smoother project timelines for contractors and developers across the country.

Conclusion

The 400TPH sand washing and screening plant in Trinidad and Tobago represents a major advancement in aggregate processing technology. By combining efficiency, sustainability, and economic benefits, it serves as a model for modern mineral processing facilities in the region. As infrastructure demands grow, such plants will continue to play a vital role in supplying essential construction materials while adhering to environmental best practices.