Nickel Ore Mobile Processing Line: A Flexible Solution for Modern Mining

Introduction to Nickel Ore Processing

Nickel is a critical metal used in stainless steel production, batteries, and various industrial applications. Extracting nickel from its ores requires specialized processing techniques. Traditional fixed processing plants are often expensive and inflexible, especially for remote or small-scale mining operations. The mobile processing line offers a cost-effective and adaptable alternative, enabling efficient nickel extraction regardless of location.

Mobile processing units integrate crushing, grinding, and separation stages into compact, transportable modules. These systems reduce logistical challenges while maintaining high recovery rates. As demand for nickel grows—particularly for electric vehicle batteries—mobile solutions are becoming increasingly relevant in the mining sector.

Key Components of a Mobile Processing Line

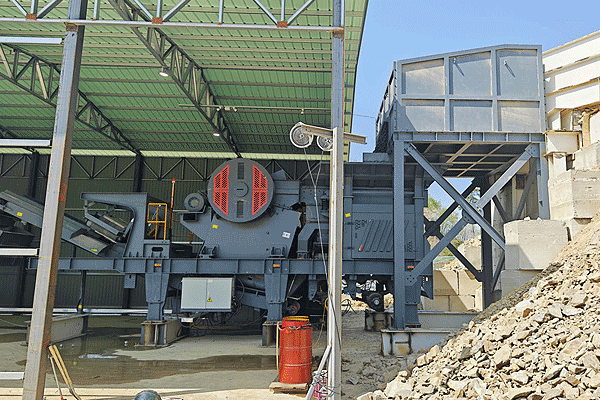

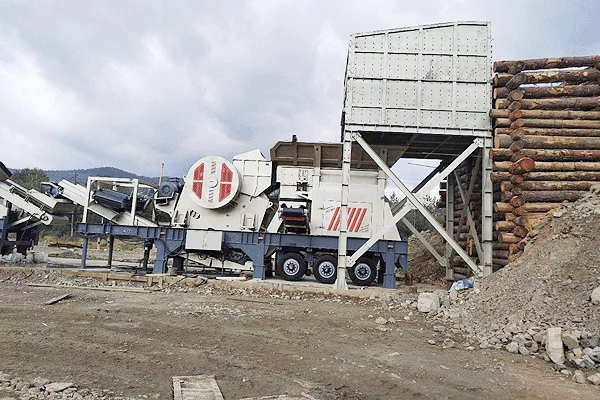

A typical nickel ore mobile processing line consists of several essential components:

- Crushing Unit – Reduces raw ore into smaller fragments for easier handling and further processing.

- Grinding Mill – Finely pulverizes the crushed ore to liberate nickel-bearing minerals.

- Separation System – Uses magnetic or flotation methods to concentrate nickel from waste material.

- Conveyors & Feeders – Ensures smooth material transfer between stages without manual intervention.

- Power Supply Module – Can be diesel-powered or connected to local grids depending on site conditions.

These components are mounted on trailers or skids, allowing quick relocation as mining operations shift between sites.

Advantages Over Fixed Plants

Mobile processing lines offer distinct benefits compared to traditional stationary plants:

- Lower Capital Costs – Eliminates the need for permanent infrastructure, reducing initial investment requirements.

- Faster Deployment – Units can be transported and assembled within weeks rather than months or years.

- Adaptability – Suitable for both high-grade deposits and lower-grade resources that may not justify a fixed facility.

- Reduced Environmental Impact – Smaller footprint minimizes land disturbance, and some models incorporate water recycling systems to reduce consumption.

These advantages make mobile solutions ideal for short-term projects or regions with unstable mineral reserves where permanent installations are impractical.

Challenges & Considerations

Despite their benefits, mobile nickel ore processors face certain limitations:

- Throughput Capacity – Typically lower than large-scale fixed plants (usually under 500 tons per hour).

- Maintenance Needs – Frequent movement increases wear on mechanical components, requiring robust servicing schedules.

- Energy Efficiency – Diesel-powered units may have higher operational costs compared to grid-connected alternatives unless optimized properly.

To mitigate these issues, operators should prioritize modular designs with easy-to-replace parts and explore hybrid power solutions where feasible. Additionally, proper workforce training ensures smooth transitions between sites while minimizing downtime during relocations.

Future Trends & Innovations

As technology advances,mobile nickel processing lines are expectedto incorporate smarter automationand sustainability features.Some emerging trends include:

–AI-Based Optimization:Real-time adjustments improve recovery rateswhile reducing energy consumption.

–Battery-Powered Systems:Renewable energy integration cuts emissionsin environmentally sensitive areas.

–Modular Expansion Capabilities:Operators can add extra unitsas production scales upwithout major overhauls.

These innovations will further enhance efficiency,making mobile solutions even more competitiveagainst conventional methodsin coming years.

Conclusion

The riseof flexible mining technologieshas positionedmobile nickleoreprocessinglinesas aviableoptionfor modernoperations.With lower upfrontcosts,faster deployment,and adaptabilityto varying deposit sizes,thesesystemsoffer apracticalalternativeespeciallyinsmalleror remoteprojects.As advancementscontinue,mobileprocessingwill likelyplayan increasinglyimportantrolein meetingglobalnickeldemand sustainablyandefficiently