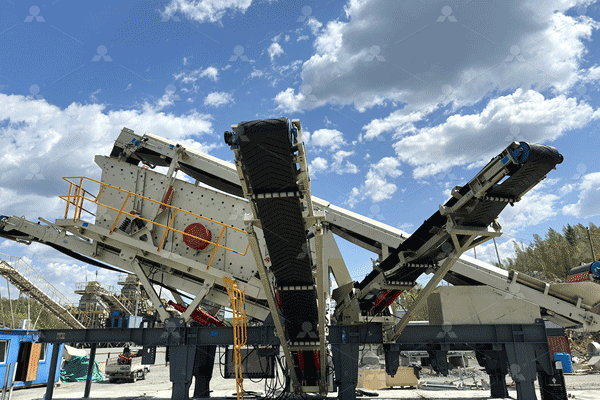

Gold Ore Mobile Crushing and Screening Line

Introduction to Gold Ore Processing

Gold ore processing begins with extracting raw material from mines, followed by crushing and screening to prepare it for further refinement. Mobile crushing and screening units have revolutionized this process by offering flexibility, efficiency, and reduced operational costs. Unlike traditional stationary plants, mobile systems can be relocated easily, making them ideal for remote mining sites or temporary operations.

These systems integrate crushers, screens, and conveyors into compact units that can be transported on trailers or tracks. Their modular design allows customization based on ore hardness, feed size, and desired output. By minimizing transportation costs and downtime, mobile solutions enhance productivity while maintaining environmental compliance.

Key Components of Mobile Crushing Systems

A typical gold ore mobile crushing line consists of several essential components:

- Primary Crusher: Usually a jaw crusher or gyratory crusher breaks large chunks of ore into smaller pieces.

- Secondary Crusher: Cone crushers or impact crushers further reduce the material size for efficient screening.

- Vibrating Screens: Separate crushed ore into different grades based on particle size.

- Conveyor Belts: Transport material between stages without manual handling.

- Power Unit: Diesel generators or electric motors provide energy independence in remote locations.

Advanced models may include automation features such as remote monitoring and real-time adjustments to optimize performance while reducing human error.

Advantages Over Stationary Plants

Mobile crushing lines offer significant benefits compared to fixed installations:

- Mobility – Units can be moved closer to mining faces, reducing haulage distances and fuel consumption.

- Quick Setup – Modular designs enable rapid assembly without extensive groundwork or infrastructure investment.

- Scalability – Additional modules (e.g., extra screens or crushers) can be integrated as production demands increase.

- Cost Efficiency – Lower capital expenditure makes them viable for small-scale miners or exploratory projects where permanent setups are impractical.

Moreover, modern units incorporate dust suppression systems and noise reduction technologies to meet strict environmental regulations worldwide—an advantage increasingly demanded by governments enforcing sustainable mining practices today!

Challenges & Solutions in Operation

Despite their advantages,mobile gold ore processing lines face certain challenges:

Uneven Feed Material Size Distribution

Irregularly sized rocks may cause blockages inside crushers leading frequent stoppages.To mitigate this issue,pre-screening feedersare often installed before primary crushing stages ensuring only appropriately sized chunks enter machinery thus improving throughput rates significantly over time! Another solution involves adjusting gap settings dynamically via hydraulic controls when dealing with varying hardness levels encountered during extraction processes—enhancing overall reliability substantially too! Additionally,wear-resistant liners(made from high-grade alloys) prolong component lifespan despite abrasive conditions commonly found within gold-bearing ores themselves… These innovations collectively minimize maintenance requirements while maximizing uptime across entire production cycles seamlessly every single day without fail whatsoever!!