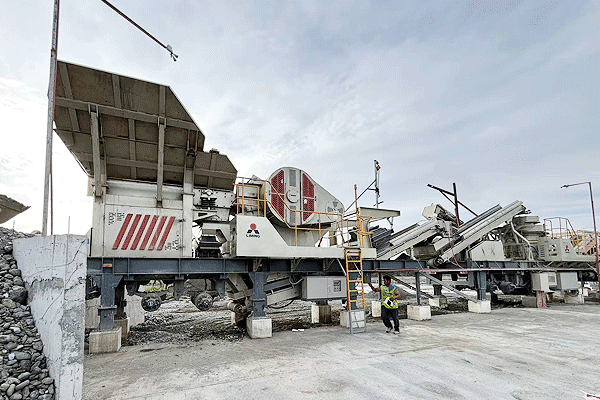

Mini Crusher Used in Urban Building Demolition

Introduction to Mini Crushers in Urban Demolition

Urban building demolition requires precision and efficiency, especially in densely populated areas where space is limited. Mini crushers have emerged as essential tools in such projects due to their compact size, versatility, and ability to process materials on-site. Unlike large crushers, mini crushers can operate in confined spaces, reducing transportation costs and environmental impact. They are commonly used for crushing concrete, bricks, and other construction debris into reusable aggregates.

These machines are particularly useful in urban redevelopment projects where traditional demolition methods may be impractical or too disruptive. By integrating mini crushers into demolition workflows, contractors can achieve faster project completion while minimizing waste.

Key Features of Mini Crushers

Mini crushers are designed with several features that make them ideal for urban demolition:

- Compact Size: Their small footprint allows operation in tight spaces such as basements or narrow streets.

- Mobility: Many models are mounted on tracks or wheels, enabling easy relocation between job sites.

- Low Noise & Emissions: Electric or hybrid models reduce noise pollution and emissions, making them suitable for residential areas.

- Adjustable Output: Operators can control the size of crushed material, producing fine or coarse aggregates as needed.

These features ensure that mini crushers meet the demands of modern urban construction while adhering to environmental regulations.

Advantages Over Traditional Demolition Methods

Using mini crushers offers several benefits compared to conventional demolition techniques:

- Reduced Waste Disposal Costs – Crushing materials on-site eliminates the need for hauling debris to landfills, saving time and money.

- Material Recycling – Crushed concrete and bricks can be reused as base material for new construction, promoting sustainability.

- Lower Environmental Impact – On-site crushing reduces truck traffic and associated carbon emissions.

- Faster Project Turnaround – Immediate processing of debris speeds up cleanup and preparation for subsequent construction phases.

These advantages make mini crushers a cost-effective and eco-friendly solution for urban demolition projects.

Challenges and Considerations

Despite their benefits, mini crushers present some challenges:

- Material Hardness Limitations: Extremely hard materials like reinforced concrete may require specialized attachments or larger machines.

- Maintenance Requirements: Regular servicing is necessary to ensure optimal performance, especially in high-use environments.

- Operator Skill Level: Proper training is essential to maximize efficiency and avoid equipment damage.

Contractors must evaluate these factors before selecting a mini crusher for their projects to ensure compatibility with job requirements.

Future Trends in Mini Crusher Technology

The future of mini crushers lies in technological advancements aimed at improving efficiency and sustainability:

- Automation & Remote Control: Some models now feature remote operation capabilities, enhancing safety in hazardous environments.

- Battery-Powered Models: Electric mini crushers with longer battery life are becoming more common, reducing reliance on diesel engines.

- AI-Assisted Crushing: Smart sensors may soon optimize crushing processes by adjusting settings based on material type automatically.

As urban construction continues to evolve, mini crushers will play an increasingly vital role in sustainable demolition practices worldwide.