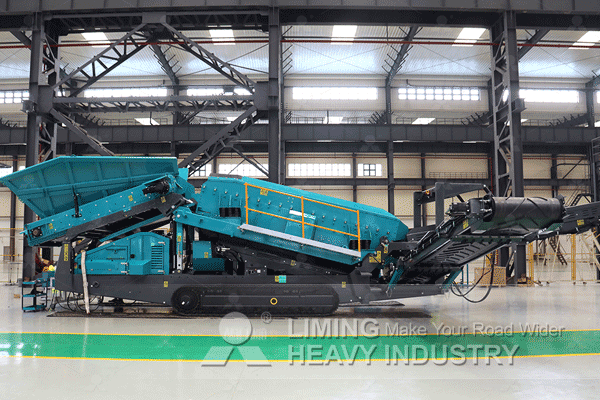

Saudi Arabia 150-200t/h Granite Portable Crushing Plant: A Mobile Solution for Hard Rock Processing

Introduction to Portable Crushing Technology

Portable crushing plants have revolutionized the mining and construction industries by offering flexible, on-site processing capabilities. In Saudi Arabia, where granite is a key resource for infrastructure projects, a 150-200t/h portable crushing plant provides an efficient solution for processing hard rock. Unlike traditional stationary setups, these mobile units reduce transportation costs and enable rapid deployment in remote locations. Their modular design ensures quick assembly and disassembly, making them ideal for temporary or shifting project sites.

Key Features of the 150-200t/h Granite Crushing Plant

This portable plant is engineered to handle granite’s high abrasiveness and compressive strength. Equipped with a robust jaw crusher as the primary unit and a secondary cone crusher, it ensures optimal size reduction. The inclusion of vibrating screens allows for precise grading of crushed material into various aggregate sizes (0-5mm, 5-20mm, etc.). Advanced automation systems monitor performance in real-time, adjusting settings to maintain efficiency while minimizing wear on components. Additionally, dust suppression systems comply with environmental regulations in Saudi Arabia.

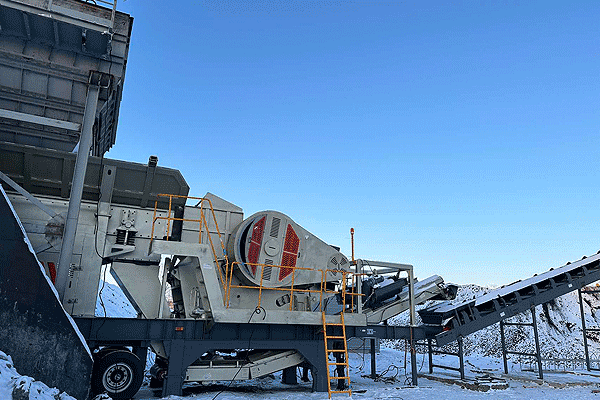

Advantages of Mobility in Harsh Environments

Saudi Arabia’s challenging terrain and extreme temperatures demand equipment that can operate reliably under tough conditions. The portable crushing plant’s mobility eliminates the need for fixed infrastructure, reducing downtime associated with relocating materials. Its compact footprint makes it suitable for confined spaces while maintaining high production rates. With fuel-efficient engines and optional solar power integration, the system minimizes operational costs—a critical factor in remote desert locations where energy supply may be limited.

Applications in Infrastructure Development

Granite aggregates processed by this plant are widely used in road construction, concrete production, and railway ballast across Saudi Arabia. The ability to produce consistent, high-quality materials on-site accelerates project timelines and ensures compliance with engineering specifications. Government-led initiatives like Vision 2030 emphasize large-scale infrastructure development, further driving demand for efficient crushing solutions that can keep pace with rapid urbanization and industrial growth.

Maintenance and Longevity Considerations

To maximize uptime, the plant incorporates easily accessible wear parts and simplified maintenance procedures. Regular lubrication points extend bearing life while hydraulic adjustment mechanisms reduce manual intervention during operation. High-grade steel components resist abrasion from granite processing while modular designs allow quick replacements without dismantling entire sections—key advantages when servicing equipment in isolated areas where technical support may be delayed or unavailable at times due to logistical constraints inherent within such regions’ geography (e.g., vast distances between urban centers).

By combining portability with robust performance metrics tailored specifically toward handling hard rock like granite under demanding climatic conditions found throughout much of Saudi Arabia’s landscape—this crushing solution stands out as both practical investment long-term sustainability goals set forth by regional stakeholders involved within construction sector developments nationwide today!