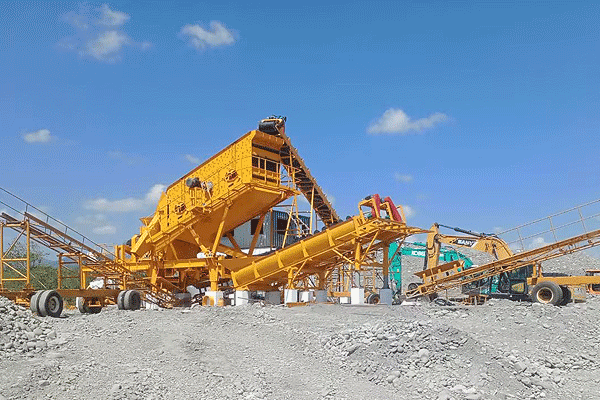

Saudi Arabia 600TPH Granite Crushing Plant: Key Aspects and Considerations

1. Introduction to the Project

The 600-ton-per-hour (TPH) granite crushing plant in Saudi Arabia is a large-scale project designed to process high-quality granite for construction and infrastructure development. Granite, known for its durability and aesthetic appeal, is widely used in road construction, building facades, and decorative applications. This plant plays a crucial role in meeting the growing demand for high-grade aggregates in the region.

The facility incorporates advanced crushing technology to ensure efficient production while minimizing environmental impact. Given Saudi Arabia’s rapid urbanization and mega-projects like NEOM and the Red Sea Development, such crushing plants are essential for supplying raw materials sustainably.

2. Crushing Process and Equipment Selection

A 600TPH granite crushing plant requires a well-optimized process flow to maximize efficiency. The typical setup includes primary, secondary, and tertiary crushing stages:

- Primary Crushing: A jaw crusher or gyratory crusher reduces large granite blocks into smaller pieces (150–300mm).

- Secondary Crushing: A cone crusher further breaks down the material into finer sizes (20–70mm).

- Tertiary Crushing: Vertical shaft impactors (VSIs) or fine cone crushers produce cubical-shaped aggregates suitable for concrete and asphalt production.

High-performance equipment from famous brands ensures reliability, low maintenance, and energy efficiency. Dust suppression systems are integrated to comply with environmental regulations.

3. Challenges in Granite Crushing Operations

Operating a large-scale granite crushing plant comes with several challenges:

- Hardness & Abrasiveness: Granite is a tough material that accelerates wear on crusher components, requiring frequent maintenance and high-quality wear parts.

- Dust Control: Strict environmental laws in Saudi Arabia necessitate effective dust suppression systems to minimize air pollution.

- Power Consumption: Large crushers consume significant energy; optimizing operations helps reduce costs while maintaining output.

Proper planning, including regular equipment inspections and operator training, mitigates these issues effectively.

4. Environmental and Regulatory Compliance

Saudi Arabia enforces stringent environmental policies for industrial projects. The granite crushing plant must adhere to regulations concerning:

- Emission Control: Installing bag filters or wet scrubbers reduces particulate emissions from crushing units.

- Noise Reduction: Sound barriers and enclosed crushers help meet noise level standards near residential areas.

- Water Recycling: Closed-loop water systems minimize water wastage during dust suppression processes.

Sustainable practices not only ensure compliance but also enhance the plant’s long-term viability by reducing fines and operational disruptions.

5. Economic Impact and Market Demand

The demand for crushed granite in Saudi Arabia continues to rise due to large-scale infrastructure projects like highways, airports, and smart cities. A 600TPH plant significantly contributes to local economic growth by:

- Creating employment opportunities for skilled workers and engineers.

- Supporting downstream industries such as concrete production and road construction firms.

- Reducing reliance on imported aggregates by boosting domestic supply capacity.

Investing in modern crushing technology ensures competitive pricing while maintaining high-quality output for buyers in both domestic and export markets.

6. Conclusion

The Saudi Arabian 600TPH granite crushing plant exemplifies how advanced technology meets industrial demands efficiently while adhering to environmental standards. By optimizing equipment selection, addressing operational challenges, and complying with regulations, this facility plays a vital role in supporting the nation’s infrastructure development goals while contributing to economic sustainability. Future expansions may focus on automation to further enhance productivity in this critical sector.