Portable Rock Crushers for Gold Mining in Zimbabwe

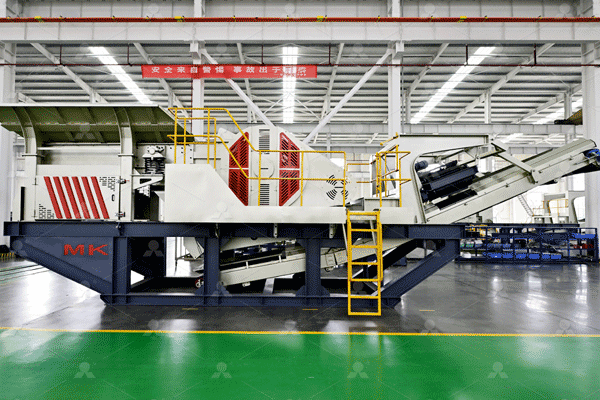

Introduction to Portable Rock Crushers

Portable rock crushers are essential tools for small-scale gold miners in Zimbabwe. These machines crush ore into smaller pieces, making it easier to extract gold. Unlike traditional crushers, portable versions are lightweight, easy to transport, and require minimal setup. They are ideal for remote mining sites where electricity may be unreliable or unavailable. Many miners rely on diesel-powered or manual models to process gold-bearing rocks efficiently. Their affordability and versatility make them a popular choice among artisanal miners seeking higher yields with lower investment costs.

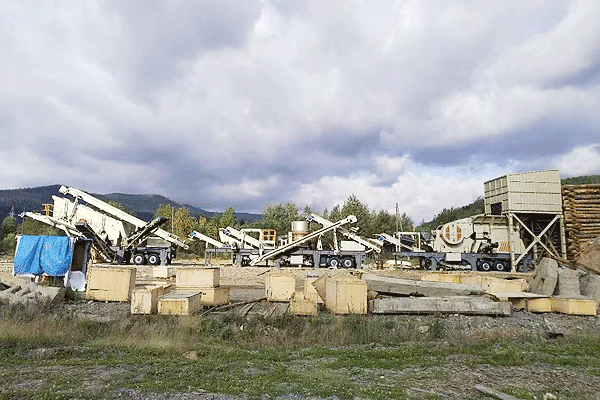

Benefits of Using Portable Crushers

The primary advantage of portable rock crushers is mobility. Miners can move them between different mining sites without heavy machinery or logistical challenges. Additionally, these crushers reduce labor intensity by automating the crushing process, allowing miners to focus on extraction rather than manual hammering. Since Zimbabwe has vast gold deposits scattered across rugged terrain, portable units help miners work flexibly while minimizing downtime. Some models also feature adjustable settings, enabling users to control output size based on their processing needs—whether for direct gold recovery or further milling operations.

Types of Portable Rock Crushers Available

Several types of portable rock crushers suit Zimbabwe’s gold mining conditions:

- Jaw Crushers: Ideal for primary crushing, these machines break large rocks into manageable chunks using compressive force.

- Hammer Mills: Best suited for secondary crushing, hammer mills pulverize ore into fine particles suitable for gold recovery methods like panning or cyanidation.

- Roller Crushers: These apply pressure between rotating cylinders to crush material uniformly with minimal dust production—useful in dry regions like Matabeleland and Mashonaland provinces.

Manual hand-operated crushers are also available for ultra-small-scale operations where fuel costs are prohibitive. Choosing the right type depends on production volume and processing requirements.

Key Considerations Before Purchase

Before investing in a portable rock crusher, miners should evaluate several factors:

- Power Source: Diesel-powered units offer independence from grid electricity but require fuel access; electric models need stable power supplies (rare in rural areas).

- Production Capacity: Higher-capacity machines process more ore per hour but may be costlier—balancing budget with expected output is crucial.

- Durability & Maintenance: Harsh mining conditions demand robust construction; opt for corrosion-resistant materials if operating near water sources like rivers or dams where oxidation risks exist due to high humidity levels year-round (common during rainy seasons).