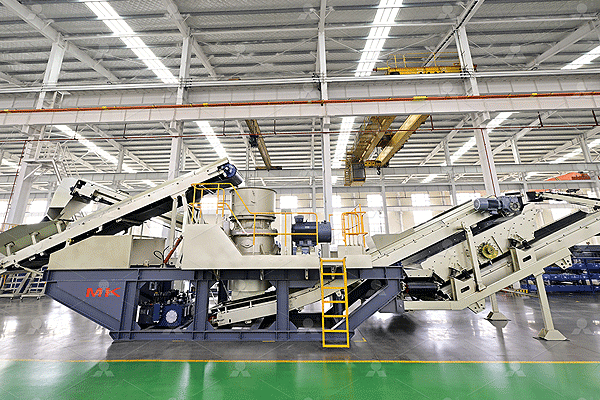

Top Rock Crushers For Your Plant

Selecting the right rock crusher is a pivotal decision that directly impacts the efficiency, cost-effectiveness, and final product quality of any aggregate or mining operation. With a variety of machines available, understanding their core functions and ideal applications is essential. This guide consolidates expert insights to help you identify the best rock crusher for your specific plant requirements.

Understanding Crusher Types and Their Core Functions

Rock crushers can be broadly categorized by their stage in the crushing process: primary, secondary, and tertiary. Primary crushers, like jaw crushers, handle the initial size reduction of large, raw material directly from the quarry face. Their main job is to break down massive rocks into manageable, coarse chunks. Secondary crushers, such as cone crushers, take this coarse material and further reduce it to a medium size. They are crucial for refining the product and improving its shape. Finally, tertiary crushers, which include impact crushers and sometimes cone crushers in a specialized role, produce the final, precisely sized product. They are masters of creating finely crushed material like sand or chip specifications for asphalt or concrete.

Each type employs a different crushing action—compression, impact, or attrition—making them uniquely suited for specific materials and desired outcomes. The choice between them depends on factors like the hardness and abrasiveness of the rock, the required production capacity, and the desired final product shape.

Key Factors for Selecting Your Ideal Machine

Choosing a crusher goes beyond simply picking a type. Several critical factors must be evaluated to ensure optimal performance in your plant. First, analyze the material characteristics. Consider its hardness, abrasiveness, density, and whether it contains any sticky or moist components that could cause clogging. A machine perfect for hard granite may not be suitable for soft limestone.

Next, define your production goals clearly. Determine the required hourly tonnage and the specific size and shape of your end products. Different projects demand different specifications; for instance, road base requires a different gradation than concrete sand. The feed opening size and the machine’s closed-side setting (CSS), which controls the output size, are fundamental technical specifications to scrutinize.

Furthermore,the initial investment is just one part of the financial picture.The total cost of ownership includes maintenance needs,ease of wear part replacement,and overall energy consumption.Different models from famous brands offer varying balances between upfront cost and long-term operational efficiency.

The Role of Jaw Crushers in Primary Crushing

Jaw crushers are the workhorses of primary crushing stages.They operate using a straightforward compression mechanism where a fixed jaw and a moving jaw create a “V” chamber.As rock enters this chamber,the moving jaw compresses it against the fixed one until it breaks into smaller pieces.Their robust design makes them exceptionally reliable for handling the toughest materials.

The primary advantage of jaw crushers is their ability to process large-sized raw feed with high reduction ratios.They are particularly effective on hard ,abrasive rocks such as basalt or granite.Their simplicity in design often translates to lower maintenance requirements and easier servicing compared to more complex machines.For any operation where raw,massive rock is the starting point,a jaw crusher is typically an indispensable first step in the size reduction circuit.

Utilizing Cone Crushers for Efficient Secondary Reduction

Cone crushers excel in secondary crushing roles.They function through a gyrating mantle within a concave bowl liner.As material enters the top ,it is compressed and crushed between the mantle and bowl liner multiple times before exiting at the bottom.This continuous compression action makes them highly productive.

A key benefit of cone crushers is their ability to produce a consistent ,well-shaped product with minimal fines generation when configured properly.They are highly efficient in medium to hard rock applications .Modern versions often come with advanced hydraulic systems that allow for automatic adjustment of settings .This provides precise control over product size .For producing high-quality aggregate for construction purposes ,a cone crusher is often an optimal choice .

Impact Crushers for Versatility and Product Shape

Impact crushers utilize impact force rather than pressure to break rock.Material is fed into a chamber where it encounters rapidly rotating hammers or blow bars .These elements throwthe material against impact plates ,shattering it upon contact.This method is excellent for producing a well-shaped,cubical product .

Their versatility allows them to handle both secondaryand tertiary crushing duties effectively .They perform exceptionally well on softer ,less abrasive materials like limestoneand recycled concrete .One significant advantageis their abilityto adjustthe outputproduct sizethrough simple changes tothe rotor speedorthe gap betweenrotorandimpact curtains .Whilewear partscan experience faster consumptionin abrasiveapplications ,their excellentproduct shapecontrolmakesthema preferredsolution formanyfinal-stagecrushingneeds .

In conclusion,the landscapeofrockcrushingequipmentis diverse .A thoroughassessmentofyourmaterial ,productiongoals,andoperationalprioritieswill guideyouto theselectionthatmaximizesyourplant’s productivityandprofitability.Factorsinfluencingcostare variedandincludecapacity,materialhardness,anddesiredspecifications,makingeachproject’srequirementunique