How to Choose the Right Secondary Crusher

Selecting the appropriate secondary crusher is a critical decision in any aggregate or mining operation. This equipment plays a pivotal role in reducing the size of material after primary crushing to prepare it for final processing. The right choice directly impacts product quality, operational efficiency, and long-term profitability. This guide consolidates expert knowledge to help you navigate the key factors in this selection process.

Understanding the Role of Secondary Crushing

The fundamental purpose of secondary crushing is to take the coarse material produced by a primary crusher and further reduce its size. This stage is not about creating the final product but rather about refining the feed for subsequent phases like tertiary crushing or screening. A well-chosen secondary crusher ensures a consistent, well-shaped product that meets specific gradation requirements. It effectively bridges the gap between initial size reduction and final product creation, optimizing the entire flow of the plant. By controlling the output from this stage, operators can significantly influence the capacity and efficiency of downstream processes, making it a linchpin for overall plant performance.

Key Factors Influencing Your Selection

Several crucial factors must be evaluated to ensure you select a crusher that aligns with your operational goals and material characteristics.

- Material Properties: The hardness, abrasiveness, density, and moisture content of the feed material are paramount. Harder, more abrasive rocks demand robust crushers designed for high wear resistance. Sticky or high-moisture materials may require specific features to prevent clogging.

- Feed Size and Desired Product: The maximum input size from your primary crusher and the required output size specification are non-negotiable starting points. The crusher must be capable of accepting your feed and reliably producing the desired product dimensions.

- Capacity Requirements: The required tons-per-hour throughput dictates the size and model of the crusher needed. Undersizing leads to bottlenecks, while oversizing results in unnecessary capital expenditure and inefficient operation.

- Moisture and Clay Content: Materials with high clay or moisture content can pose challenges like packing and blocking. In such cases, certain crusher types that utilize impact and throwing action are often more suitable than those relying solely on compression.

- Overall Plant Flow: The secondary crusher must integrate seamlessly with existing primary and tertiary stages, as well as screening equipment. A mismatch can create inefficiencies throughout the entire system.

A Comparative Look at Common Crusher Types

Different crusher technologies excel in different applications. Here is an overview of common secondary crushers:

- Cone Crushers: These are predominant in hard rock applications. They work through compression crushing, where material is squeezed between a rotating mantle and a stationary concave. They are renowned for producing well-shaped, cubicle products with low wear costs in abrasive environments.

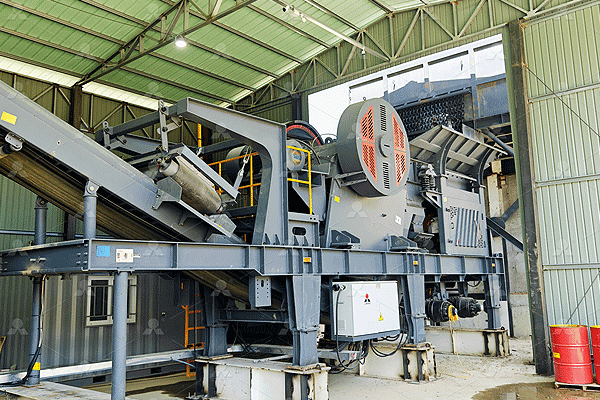

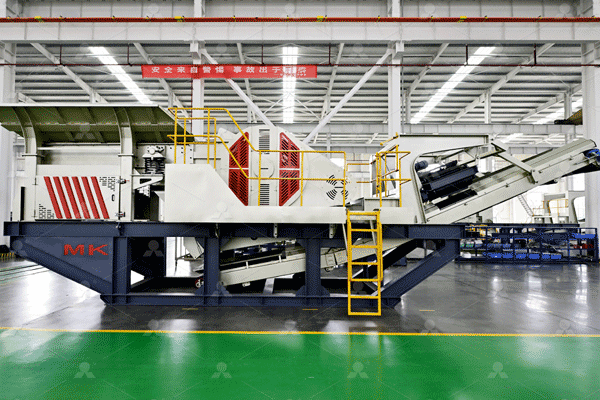

- Impact Crushers: These crushers utilize impact force to break rock. They are highly effective for processing softer, less abrasive materials like limestone and recycled concrete. Impact crushers excel at producing a high ratio of reduction and are valued for their excellent product shape.

- Jaw Crushers (as Secondary): While typically primary units, certain jaw crusher models can serve effectively in a secondary role, especially when processing softer materials or when a simpler plant layout is desired.

Each type has distinct advantages; cone crushers offer reliability in hard rock, while impact crushers provide versatility and superior shape in softer materials.

Matching Material Characteristics to Crusher Type

The nature of your feed material should be the primary driver behind your technology choice.

For processing hard, abrasive rocks such as granite or basalt, cone crushers are generally considered superior due to their steady compression action and robust construction that withstands wear over time.

For softer, less abrasive materials like limestone or asphalt millings from demolition projects, impact crushers often present a more efficient solution because they deliver higher reduction ratios without over-stressing components.

When dealing with mixed or recycled materials containing elements like rebar or wood—common in construction waste—impactors with their ability to handle occasional uncrushable objects through hydraulic opening systems offer distinct operational advantages over other types which may be more susceptible to damage from tramp metal.

Evaluating Operational Costs Beyond Initial Purchase

The initial investment is only one part of the total cost of ownership; long-term operational expenses often have a greater financial impact over time.

Key cost drivers include wear parts consumption—the frequency at which liners (mantles/concaves), blow bars need replacement varies significantly between different machines depending on application severity—and energy efficiency: some designs inherently consume less power per ton processed than others under similar conditions which translates into substantial savings on electricity bills annually if operating continuously at high capacities; maintenance requirements also differ widely among various technologies so considering service accessibility along with availability/price structure for spare parts from suppliers becomes essential when making comparisons between options available today from famous brands worldwide whose offerings differ substantially regarding these aspects even within same category equipment lines themselves!

Furthermore influencing price factors include many variables such as specific technical requirements desired output specifications leading different configurations being necessary thus making direct price comparisons difficult without detailed project analysis first hand by qualified professionals familiar with all nuances involved here!

Conclusion: Making an Informed Decision

Choosing an optimal secondary crushing solution requires careful consideration beyond simple catalog specifications alone! You must analyze your unique combination including raw material properties targeted end-products required production rates alongside comprehensive understanding about both capital outlay versus lifetime running costs associated each potential candidate machine type available market today before committing any particular model brand ultimately ensuring maximum return investment through enhanced productivity reduced downtime throughout its service life within your operation’s specific context environment constraints present onsite location wise too!