Top 3 Crushing Set-ups for Concrete Recycling

Concrete recycling is a cornerstone of sustainable construction, transforming demolition waste into valuable aggregate. The efficiency and profitability of this process hinge on selecting the right crushing setup. Different configurations cater to varying project scales, material compositions, and final product requirements. This article explores three of the most effective and widely adopted crushing configurations in the industry today, detailing their operational principles and ideal applications to guide your selection process.

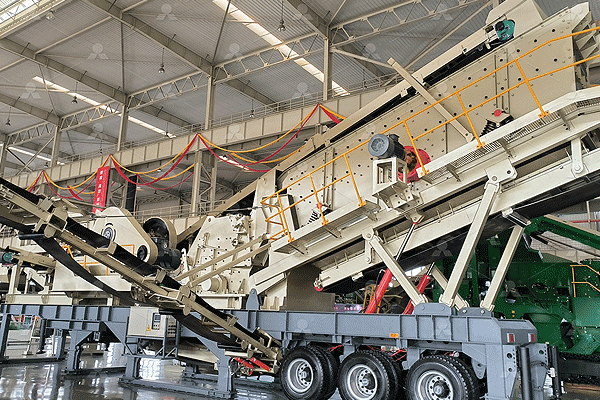

1. The Mobile Jaw Crusher and Mobile Screener Combination

This setup is arguably the most popular for concrete recycling projects, especially those requiring high mobility and operational flexibility. The core of this configuration is a mobile jaw crusher, which serves as the primary crushing unit. It is typically paired with a mobile screener to separate the crushed material into different sizes on-site.

The process begins with the mobile jaw crusher breaking down large chunks of demolished concrete into smaller, more manageable pieces. The powerful jaw plates apply compressive force to fracture the material. Once the initial crushing is complete, the output is conveyed to a mobile screener. This machine sorts the aggregate into various specified sizes—such as base course, drainage stone, or finer grades for new concrete mixes. Any oversized material is often sent back to the crusher for further processing in a closed-loop system.

The primary advantage of this setup is its unparalleled mobility and quick setup time. These self-propelled units can be transported directly to a demolition site, eliminating the need for multiple trucks to haul raw material to a fixed plant. This significantly reduces transportation costs and environmental impact. It is perfectly suited for urban construction sites, road rehabilitation projects, and smaller-scale recycling operations where the work location changes frequently.

2. The Impact Crusher System for Superior Final Shaping

When the goal is to produce a high-quality, well-shaped final product directly from the crusher, an impact crusher system is often the preferred choice. Unlike jaw crushers that use compression, impact crushers utilize rapid impacts from hammers or blow bars on a rotating rotor to shatter the concrete. This method inherently produces a more cubical end product.

In this configuration, an impact crusher can function as both a primary and secondary crusher in a single unit, especially for less heavily reinforced concrete. For tougher materials with significant rebar, it may follow a jaw crusher in a two-stage process. The key feature of an impact crusher is its ability to control the final product’s shape and size precisely through adjustable aprons and rotor speed.

This setup excels in producing aggregates for high-specification applications like asphalt production (where angular particles are crucial for strength) or architectural exposed aggregate. The cubical particles interlock better than flaky ones, resulting in a more stable and durable end-product. While some mobile impact crushers exist, this system can also be configured as a stationary or semi-mobile plant for large-volume, long-duration recycling projects at a dedicated facility.

3.The Jaw Crusher and Cone Crusher Tandem for High-Volume Processing

For large-scale concrete recycling plants that demand high throughput and consistent production of multiple aggregate sizes over a long period, the tandem of a jaw crusher and a cone crusher represents a classic and highly efficient solution. This configuration establishes a clear two-stage crushing circuit that maximizes output and product control.

In this system, the jaw crusher acts as the robust primary workhorse, taking in large demolition slabs and reducing them to a medium-sized rubble. This material is then fed into a cone crusher for secondary reduction. Cone crushers operate by compressing material between a gyrating mantle and a stationary concave liner. They are exceptionally efficient at creating finer grades of aggregate and are known for their reliability and low operating costs per ton.

This setup is ideal for fixed or semi-permanent recycling yards that receive concrete waste from numerous demolition sites across a region. Its strength lies in its ability to process very hard and heavily reinforced concrete consistently while offering excellent control over particle size distribution through adjustments on the cone crusher’s closed-side setting (CSS). While it requires more initial infrastructure than fully mobile solutions like Setup 1 or 2 (e.g., conveyors), its superior efficiency makes it unbeatable for high-tonnage operations focused on long-term profitability.

Conclusion

Selecting among these top crushing setups depends entirely on your specific operational needs—mobility requirements, desired final product specifications (shape/size), project scale/duration,and budget considerations.It’s important to note that numerous factors influence overall investment; different performance requirements lead to different configurations which consequently affect cost structures.Consulting with industry experts can help you analyze your situation thoroughly before investing in equipment that will deliver optimal returns from your concrete recycling endeavors