Primary vs. Secondary Sizer Crusher: Key Differences in Usage

In the world of material reduction, sizer crushers play a pivotal role in handling various raw materials efficiently. Understanding the distinction between primary and secondary sizer crushers is crucial for optimizing operations in industries like mining, quarrying, and recycling. While both types utilize intermeshing shafts or rotors to crush materials through compression and shear forces, their applications, design features, and operational requirements differ significantly. This article explores the key differences in usage between primary and secondary sizer crushers, providing insights to help you make informed decisions for your projects.

Function and Application Scope

Primary sizer crushers are designed as the initial stage in a crushing circuit, where they handle large, raw feed material directly from the source, such as a mine or quarry. Their main function is to reduce oversized rocks, ores, or other bulky materials to a manageable size for further processing. Typically, these crushers accept input with high feed sizes—often ranging from several hundred millimeters up to over a meter in diameter—and produce a coarse output that may be suitable for direct use or as feed for secondary crushing. They excel in high-capacity scenarios where throughput is prioritized over fine product sizing.

In contrast, secondary sizer crushers are employed later in the process chain, following primary crushing. They take pre-crushed material from the primary stage and refine it into smaller, more uniform particles. The focus here is on achieving precise product specifications, such as specific grain sizes or shapes required for end-use applications like construction aggregates or industrial minerals. Secondary crushers often handle materials with lower feed sizes but require higher precision in output control.

The choice between primary and secondary usage depends on factors like material hardness, abrasiveness, and desired final product characteristics. For instance, primary sizers are ideal for soft to medium-hard materials where high reduction ratios are needed upfront.

Design and Structural Variations

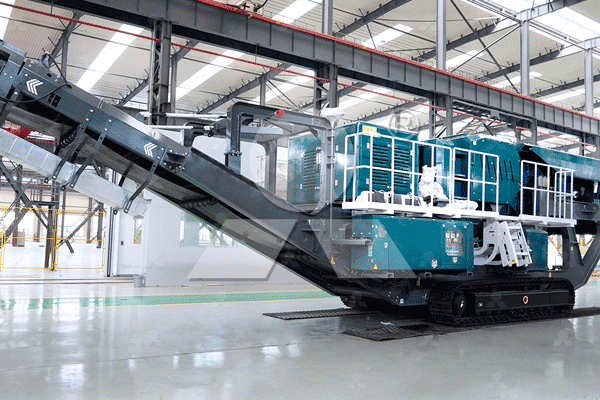

The design of primary sizer crushers emphasizes robustness and durability to withstand the impact of large, unpredictable feed materials. They typically feature heavier frames, larger rotors or shafts with high-torque capabilities.

Secondary sizer crushers prioritize precision and efficiency in particle size reduction. Their designs often incorporate finer adjustments for gap settings between rotors or shafts.

Material flow considerations also differ; primary units may include features like hydraulic adjustment systems for quick changes under load.

Operational Parameters and Performance

Operational parameters highlight distinct usage patterns between primary and secondary sizer crushers. Primary crushers operate under high-load conditions with coarse feed.

Secondary crushers focus on controlled reduction with finer inputs.

Performance metrics vary accordingly; primary units are evaluated on throughput capacity.

Material Suitability and Limitations

Both types of sizer crushers are versatile but have specific material suitability profiles based on their design intent.Primary sizers excel with soft to medium-hard materials like coal limestone gypsum or clay where high moisture content isn’t a major issue due to their ability to handle sticky feeds without clogging easily . However they might struggle with extremely abrasive rocks unless equipped with specialized wear protection which can increase operational costs over time .

Secondary sizers perform best when processing pre-crushed medium-hard to hard materials such as basalt granite or recycled concrete where precise shaping is needed . They are less suited for very wet or clay-rich feeds that could cause packing between rotors leading to downtime . Understanding these limitations helps prevent premature wear or inefficiencies—for example using a primary-style sizer for secondary duties might result in excessive fines generation while deploying a secondary model as a primary unit could lead to overload failures .

Economic Considerations

When selecting between primary and secondary sizer crushers economic factors play a significant role beyond just initial purchase costs which vary based on configuration size and customizations required . Primary models often involve higher capital investment due to their heavy-duty construction but offer long-term savings through reduced downtime in demanding applications . Maintenance costs can be substantial especially if abrasive materials are processed requiring frequent component replacements ; however modular designs from famous brands sometimes ease this burden by allowing partial repairs instead of full replacements .

For secondary units operational expenses might center more on energy consumption per ton of output since finer crushing demands more power relative to volume processed . The total cost of ownership should account for factors like expected lifespan spare parts availability and compatibility with existing plant layouts — all influencing overall profitability without direct price comparisons being feasible due to project-specific variables .

In summary recognizing the key differences in usage between primary and secondary sizer crushers enables better alignment with operational goals ensuring efficient material processing tailored to specific industry needs while balancing performance durability and economics effectively