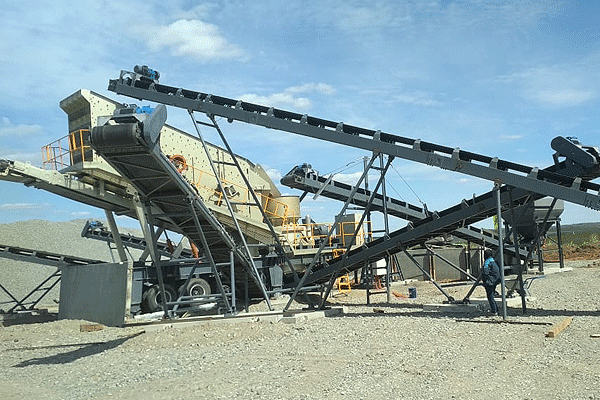

River Stone Crushing Plant in the Philippines

River stone is a naturally formed, hard, and durable material, making it a highly sought-after resource for construction and infrastructure projects. In the Philippines, with its ongoing development and abundance of river systems, establishing an efficient river stone crushing plant is a crucial undertaking. This process transforms raw, bulky river stones into various sizes of aggregates needed for concrete production, road bases, and other building applications. A well-designed crushing operation is key to maximizing the value of this natural resource while ensuring operational efficiency and cost-effectiveness.

Understanding River Stone as a Raw Material

Before setting up a crushing plant, it is essential to understand the unique properties of river stone. Unlike other quarry rocks, river stones are typically rounded and smooth due to prolonged water erosion. This shape can present both challenges and advantages in the crushing process. Their natural hardness ensures that the resulting aggregates are strong and resistant to wear, which is ideal for producing high-quality concrete.

However, their smooth surface can sometimes lead to lower adhesion in asphalt mixes if not processed correctly. The composition of river stone is generally consistent, often consisting of granite, basalt, or quartzite, which are known for their high compressive strength. This consistency is beneficial for producing uniform end-products. The size of the raw river stones collected from the riverbed can vary significantly, requiring a primary crushing stage capable of handling large rocks.

Essential Equipment Configuration for the Plant

A successful river stone crushing plant relies on a well-planned combination of machinery. The core of the operation is the crusher unit itself. A typical setup involves multiple stages of crushing to achieve the desired product sizes efficiently. For primary crushing, a jaw crusher is often employed due to its robust ability to handle large-sized raw materials and its high reduction ratio. It breaks down the large river stones into smaller, manageable pieces.

Following this, a secondary crusher, such as a cone crusher or an impact crusher, is used for further refinement. Cone crushers are particularly well-suited for hard and abrasive materials like river stone, as they provide a consistent product size and are efficient in operation. For final shaping and producing high-quality sand (manufactured sand), an impact crusher or a sand maker can be integrated into the system. Supporting equipment like vibrating feeders, vibrating screens for sorting different aggregate sizes, and conveyor belts are indispensable for creating a smooth and automated production line.

Key Considerations for Plant Setup and Operation

Selecting an optimal location is one of the most critical decisions when establishing a crushing plant in the Philippines. Proximity to the raw material source minimizes transportation costs for river stones. Furthermore, consideration must be given to logistics; the site should have good access to roads for transporting finished aggregates to market or project sites.

Environmental factors cannot be overlooked. Dust suppression systems, such as water sprays or dust collectors, are mandatory to control particulate emissions and comply with local regulations. Noise control measures should also be implemented to minimize impact on nearby communities if applicable.

Operational efficiency hinges on proper planning of the plant layout. The arrangement of crushers, screens, and conveyors should facilitate a logical material flow without bottlenecks or excessive re-handling.

Economic Viability and Investment Analysis

Investing in a river stone crushing plant in the Philippines represents a significant but potentially rewarding venture given the country’s steady demand for construction aggregates.The initial investment covers land preparation equipment purchase installation costs among others When considering equipment numerous factors influence cost including production capacity required final product specifications level automation desired Different configurations naturally lead different investment levels

Beyond initial outlay operating costs form major part financial equation These include energy consumption maintenance spare parts labor Effective maintenance strategy crucial minimize downtime extend machinery lifespan Maximizing return investment requires strategic approach such producing diverse range aggregate sizes cater broader market optimizing operational workflow reduce waste enhance overall productivity