Unlocking Efficiency: The 200 TPH River Stone Mobile Crusher

In the dynamic world of aggregate processing, efficiency and mobility are paramount. The 200 TPH (tons per hour) mobile crusher designed specifically for river stone has emerged as a game-changing solution for medium-scale operations. This plant perfectly balances high production capacity with the flexibility of movement, allowing contractors to process material directly at the source. By eliminating the need for multiple fixed installations and reducing transportation costs, it offers a significant boost to operational profitability. This article delves into the core aspects of this versatile machinery, exploring its key components, operational advantages, and critical selection criteria to guide your investment decision.

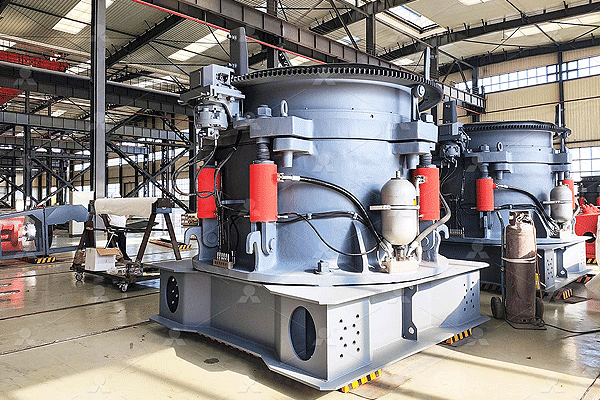

Core Components and Working Principle

A 200 TPH river stone mobile crusher is not a single machine but a sophisticated, integrated system mounted on a robust chassis for easy transport. The primary component is the crusher itself, which is often a jaw crusher or an impact crusher, chosen for its ability to break down hard and abrasive river stone. The plant is powered by a reliable diesel engine or can be connected to an external power source, ensuring operation in remote locations.

The process begins with raw river stone being fed into a vibrating feeder, which regulates the flow of material to prevent overloading the crusher. A preliminary screening unit, or pre-screen, may separate finer particles before they enter the crushing chamber, enhancing overall efficiency. The core crushing action then reduces the stone to smaller sizes. Subsequently, crushed material is conveyed to a vibrating screen where it is sorted into various finished product sizes. Any oversized material is recirculated back into the crusher for further processing in a closed-circuit system, ensuring a consistent and precisely graded final product.

Key Advantages for River Stone Processing

The primary benefit of this mobile solution is its unparalleled on-site mobility. It can be quickly transported between job sites or moved around a single large site as needed, drastically cutting down on trucking costs associated with hauling raw material to a fixed plant. For river stone applications, this means setting up directly at the quarry or near the riverbank.

Furthermore, these plants are engineered to handle the specific challenges of river stone, which is typically round, hard, and can contain varying levels of silica. The robust construction of key wear parts and optimized crushing chambers ensure high reduction ratios and consistent output shape. The integrated screening system allows for simultaneous production of multiple aggregate specifications—such as base course, chips, and sand—from a single feed of river stone. This multi-product capability maximizes resource utilization and increases revenue potential from every ton processed.

Crucial Factors Influencing Your Selection

Selecting the right 200 TPH mobile crusher requires careful consideration beyond just the production capacity. First, you must analyze the physical properties of your specific river stone deposit—its hardness, abrasiveness, and initial size distribution will determine whether a jaw crusher for primary breaking or an impact crusher for superior grain shape is more suitable.

The final product requirements are equally important. If you need to produce high-quality manufactured sand as one of your end products, you should consider a plant that can integrate a sand-making module or an additional cone crusher for finer crushing. The choice of power source—diesel-electric or fully electric—will impact your long-term fuel costs and operational flexibility. Numerous other factors influence the final investment; different requirements lead to different configurations which consequently affect overall project economics.

Essential Operational Maintenance Tips

To ensure your mobile crusher consistently delivers 200 TPH when processing tough river stone, a disciplined maintenance routine is non-negotiable. Daily inspections should focus on key wear parts like jaw plates, blow bars, and screen meshes. Given river stone’s abrasive nature, these components will experience wear and must be monitored closely to maintain product quality and prevent unexpected downtime.

Regularly check hydraulic systems for leaks and ensure fluid levels are correct. Greasing all bearings according to the manufacturer’s schedule is critical for longevity in dusty environments. Operators should also make it a habit to visually inspect conveyor belts for signs of misalignment or damage before and after each shift. Keeping the control system clean and protected from dust and moisture will ensure reliable operation over the long term.

Making an Informed Investment Decision

Investing in any major piece of equipment demands thorough research beyond simply finding one “for sale.” A 200 TPH mobile crusher represents significant potential for growth but requires alignment with your operational goals.

Before committing:

- Verify that reputable brands provide strong after-sales support.

- Ensure spare parts are readily available.

- Request detailed performance data.

- Seek case studies from similar applications.

Ultimately choosing such equipment involves evaluating total cost ownership versus expected return investment through increased production efficiency reduced logistical expenses inherent mobile design offers modern aggregate producer powerful tool staying competitive market