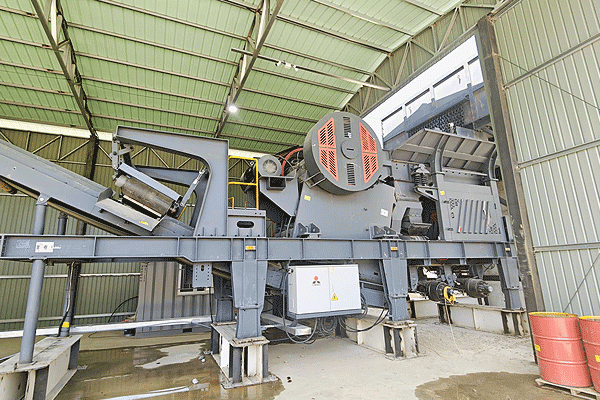

River Stone Crushing Plant in the Philippines

River stone is a naturally formed, hard, and high-quality aggregate resource widely found in the Philippines. Processing this material into high-grade sand and gravel through a specialized river stone crushing plant is a critical operation for the local construction and infrastructure sectors. This article provides a professional overview of setting up an efficient river stone crushing plant, covering key aspects from equipment selection to operational best practices.

1. Understanding the Raw Material: Philippine River Stone

Before designing a crushing plant, a thorough analysis of the raw material is paramount. River stones in the Philippines are typically characterized by their high hardness, high silica content, and relatively clean, weathered surfaces from long-term water erosion. Their compressive strength is generally high, which demands robust crushing equipment. However, their natural round and smooth shapes can present challenges for initial crushing and achieving good adhesion in cement mixtures.

A professional material test is highly recommended. This test determines key properties such as abrasiveness, hardness (e.g., on the Mohs scale), and the size distribution of the raw feed. The results directly influence the choice of crusher types and liner materials. For instance, highly abrasive stone requires crushers with wear-resistant components and specific crushing chambers designed to minimize wear. Understanding these characteristics ensures the selected plant configuration is not only effective but also cost-efficient in terms of maintenance and energy consumption over its lifespan.

2. Core Equipment Configuration for Crushing Plants

The heart of any river stone crushing operation is its machinery lineup. A well-designed flow typically includes three or more stages: primary crushing, secondary crushing, and tertiary/fine crushing.

- Primary Crushing: A jaw crusher is almost universally used for the first stage. It is designed to handle large-sized river stones, reliably reducing them to a manageable size of around 150-200mm. Its robust construction and powerful compression force make it ideal for breaking down hard rock.

- Secondary Crushing: For further reduction, a cone crusher is often the preferred choice for hard stones like river gravel. Its principle of laminated crushing squeezes rock between a mantle and a concave, producing a well-shaped, cubicle product with fewer flaky particles compared to impact crushers.

- Tertiary/Fine Crushing: To produce high-quality sand or very fine aggregates, an impact crusher (specifically a vertical shaft impactor or VSI) can be employed. A VSI crusher uses a high-speed rotor to throw stones against anvils, resulting in an excellent particle shape through rock-on-rock or rock-on-iron breaking.

Supporting equipment like vibrating feeders, pre-screening scalpers, and multiple-deck vibrating screens are crucial for separating material efficiently and ensuring each crusher is fed only with the appropriate size fraction.

3. Key Considerations for Plant Setup

Several critical factors must be addressed when establishing a river stone crushing plant in the Philippine context.

- Site Selection and Environment: The plant should be located as close to the raw material source as possible to minimize transportation costs. It’s crucial to conduct an environmental impact assessment and secure all necessary local permits.

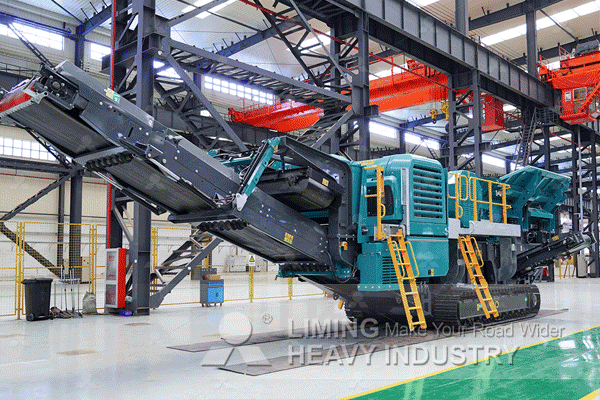

- Mobility Requirement: For projects involving multiple sites or moving along a riverbed, mobile crushing plants are highly advantageous.

- Power Source: The choice between grid electricity and diesel generators depends on the site’s remoteness and infrastructure.

- Final Product Specifications: The target sizes and proportions of finished products (e.g., 0-5mm sand, 5-10mm gravel) dictate the final screen configurations.

- Labor and Maintenance: A skilled team for operation.

- Laboratory Setup: A small on-site lab for regular quality control checks on particle size distribution ensures consistent product quality that meets project specifications.

4. Operational Efficiency and Maintenance Protocols

Maximizing uptime and productivity requires disciplined operational practices.

A preventive maintenance schedule is non-negotiable. This includes regular inspection and replacement of wear parts like jaw plates, cone mantles/concaves, VSI rotors/anvils,

and screen meshes.

Monitoring wear rates helps predict part lifecycles

and plan changes during scheduled downtime,

preventing unexpected failures.

Lubrication systems,

especially for large bearings in cone crushers,

must be meticulously maintained.

Operational efficiency also involves optimizing

the entire production line.

This means ensuring that each crusher

is running at its optimal feed level

and closed-side setting,

and that conveyor belts are properly loaded

to avoid spillage or bottlenecks.

Regular calibration of screens ensures accurate sizing,

preventing oversized material from reaching downstream crushers

or under-sized material from bypassing them,

which protects equipment

and guarantees product quality.

5. Economic Viability Analysis

Investing in a river stone crushing plant represents significant capital expenditure; however,

its economic viability can be substantial given strong market demand.

The initial investment cost varies considerably based on several factors including production capacity required equipment configuration (stationary vs mobile)

and level of automation integrated into system design

Factors influencing overall project economics include:

Daily operational hours fuel or electricity consumption costs labor expenses maintenance part inventories financing costs if applicable Ultimately profitability hinges upon efficiently producing aggregates that meet stringent quality standards demanded by construction industry while managing operational expenditures effectively Long term success depends not just on initial setup but also strategic planning around market needs logistical advantages offered by location