A Comprehensive Guide to 100-200 TPH Limestone Crusher Plant Investment

Investing in a limestone crushing plant with a capacity of 100 to 200 tons per hour (TPH) is a significant decision for any aggregate production operation. This mid-range capacity is highly popular for medium to large-scale projects, offering an optimal balance between output and investment. Understanding the total plant cost involves more than just the price tag of machinery; it requires a holistic view of the entire system, from core components to operational logistics. This guide breaks down the key factors influencing your investment in a robust 100-200 TPH limestone processing solution.

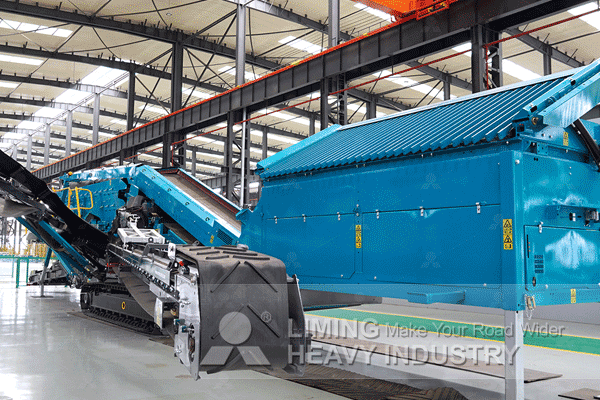

Core Components and Configuration of the Crushing Circuit

The heart of any crushing plant lies in its configuration, which directly dictates performance, final product shape, and overall cost. For processing abrasive materials like limestone, a well-designed circuit is paramount. A typical setup for this capacity range often involves a two or three-stage crushing process.

Primary crushing is usually handled by a robust jaw crusher, which reduces the large raw limestone rocks into smaller, manageable sizes. The secondary crushing stage often employs an impact crusher or a cone crusher. Impact crushers are excellent for producing a well-graded, cubical product, which is highly desirable for concrete and asphalt applications. Cone crushers offer great efficiency and are ideal for harder variants of limestone, providing consistent output. Following this, a vibrating screen sorts the crushed material into various sizes, with oversized particles being recirculated back to the secondary crusher in a closed-circuit system. The specific combination of these machines—whether it’s a “jaw + impact” or “jaw + cone” layout—is a primary factor in determining the plant’s capital outlay and operational efficiency.

Key Factors Influencing the Overall Plant Investment

When evaluating the cost of a 100-200 TPH limestone crusher plant, it’s crucial to recognize that many variables are at play. The final investment is not a single figure but a sum of interconnected factors.

First, the choice of machinery itself carries significant weight. The brand’s reputation for quality and durability can affect the initial price point. Furthermore, the selected configuration plays a role; a more complex three-stage circuit with additional screening units will naturally command a higher investment than a simpler two-stage setup. Beyond the crushers and screens, auxiliary equipment like feeders, conveyors, hoppers, and dust suppression systems are essential and contribute to the total cost.

Second, site-specific considerations are equally important. The need for foundational work, electrical infrastructure upgrades, and proximity to the quarry face all influence installation expenses. Labor costs for operation and maintenance also vary by region. Therefore, two plants with identical theoretical output can have vastly different total project costs based on these logistical and geographical factors.

Operational Efficiency and Long-Term Value

Beyond the initial capital expenditure (CAPEX), savvy investors pay close attention to operational expenditure (OPEX), which defines long-term profitability. A slightly higher upfront cost for a more efficient plant can lead to substantial savings over its lifespan.

Key operational cost drivers include wear parts consumption. Limestone is abrasive and will wear down jaw plates, blow bars, and mantles rapidly. Investing in crushers designed for easy maintenance and equipped with durable wear parts can drastically reduce downtime and replacement costs. Energy consumption is another major factor; modern electric-driven plants are generally more efficient than diesel-powered ones, though they require a stable power source.

Additionally,a well-designed plant layout that minimizes material travel distance between components can improve fuel or electricity efficiency and reduce conveyor belt wear.Focusing on these aspects of operational efficiency ensures that your plant remains productive and cost-effective long after commissioning.

Strategic Selection for Optimal Return on Investment

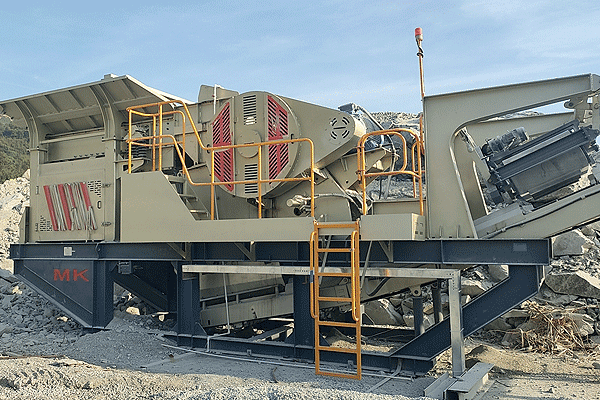

Selecting the right 100-200 TPH limestone crusher plant is ultimately about aligning your equipment with your business goals.The required final product specifications—such as size gradation and rock shape—will dictate whether an impact-centric or cone-centric secondary stage is more suitable.If producing high-quality aggregates for construction is the goal,a configuration that emphasizes product cubicity is essential.

Furthermore,the plant’s mobility should be considered.A stationary plant is ideal for long-term projects near a fixed quarry location.For operations that require moving between sites,a mobile or semi-mobile crushing solution might be more appropriate despite potentially higher initial costs due to their inherent mobility.Ultimately,the goal is to achieve an optimal balance between performance,cost,and flexibility to ensure maximum return on investment over many years of reliable service.A thorough analysis of production needs alongside expert consultation will guide you toward making an informed decision that supports sustainable growth