Waste Concrete Block River Gravel Hydraulic Stone Crushing Machine Price

Introduction to the Machine and Its Core Function

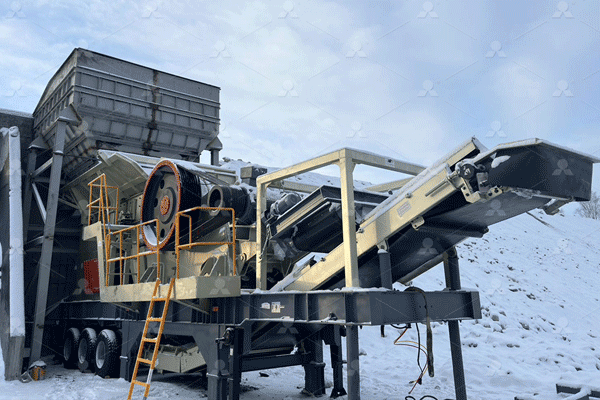

The waste concrete block river gravel hydraulic stone crushing machine represents a significant advancement in material processing technology. This equipment is specifically engineered to handle hard and abrasive materials such as discarded concrete blocks, natural river gravel, and various other types of stones. Its primary function is to reduce these bulky materials into smaller, uniform aggregates of specific sizes. The core of its operation lies in a powerful hydraulic system that provides the immense force needed to fracture these tough materials efficiently.

Unlike traditional crushers that rely on mechanical linkages, this machine utilizes hydraulic pressure to control the crushing jaws or impact hammers. This results in a more powerful and controllable crushing action. The aggregates produced are essential raw materials for new construction projects, road bases, and landscaping, effectively turning construction and demolition waste into valuable resources. This process not only solves the problem of waste disposal but also promotes sustainable development by conserving natural raw materials.

Key Advantages of Hydraulic-Driven Crushing Systems

The adoption of hydraulic systems in stone crushing machinery offers several distinct benefits over conventional models. One of the most notable advantages is the exceptional level of control it provides. Operators can precisely adjust the pressure and speed of the crushing components, allowing for real-time optimization of the process based on the material’s hardness and size. This leads to a more consistent final product with fewer oversized or undersized particles.

Furthermore, hydraulic crushers are renowned for their built-in safety mechanisms. The hydraulic system acts as a shock absorber; if an unbreakable object like tramp iron enters the crushing chamber, the hydraulic cylinders can automatically release pressure, allowing the object to pass through or be cleared without causing significant damage to the machine. This feature drastically reduces the risk of costly breakdowns and extends the operational life of the equipment. Additionally, these machines often operate with less noise and vibration, contributing to a better working environment.

Critical Factors Influencing Equipment Selection

Choosing the right hydraulic crushing machine requires careful consideration of several key factors to ensure it meets specific operational needs. The primary consideration is the nature of the raw material. The hardness, abrasiveness, and size of the initial feed, such as reinforced concrete blocks versus softer river gravel, directly determine the required machine robustness, power, and wear-resistant components.

Another crucial factor is the desired output capacity and final product specifications. Different projects require different aggregate sizes and shapes. Therefore, understanding the required tons-per-hour output and the exact gradation of the finished product is essential for selecting a machine with adequate power and appropriate crushing chamber design.

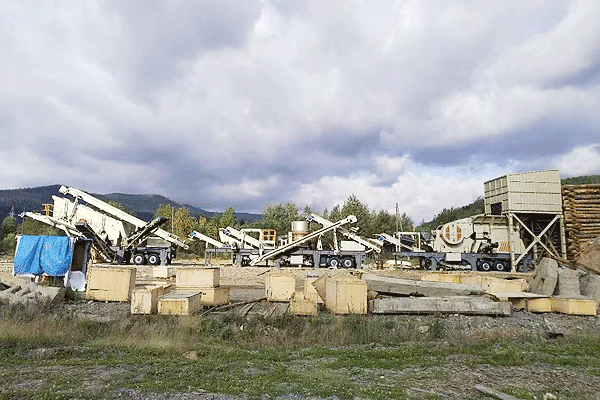

Finally, mobility should be considered based on project logistics. For fixed-site recycling plants, a stationary model is ideal. However, for contractors who move between multiple job sites or need to process material directly at its source, a mobile unit mounted on a tracked or wheeled chassis offers unparalleled flexibility and efficiency by eliminating transportation costs for raw materials.

Understanding Investment Considerations

When evaluating this type of machinery from an investment perspective, it’s important to recognize that several variables influence its overall cost structure rather than a single fixed price tag. The factors affecting investment include production capacity requirements; higher output models naturally involve greater capital outlay due to larger engines and heavier-duty components.

The specific configuration also plays a major role in determining cost differences between various options available on market today from famous brands worldwide . A basic configuration will differ significantly in investment compared to one equipped with advanced features like automated control systems , integrated screening units , or enhanced dust suppression technologies . Furthermore , long-term operating expenses such as energy consumption , maintenance schedules , availability , durability replacement parts must be factored into any comprehensive financial analysis before making purchase decision .

Conclusion: A Strategic Asset for Modern Operations

In summary , waste concrete block river gravel hydraulic stone crushing machine stands as powerful versatile solution modern recycling aggregate production industries Its superior efficiency inherent safety features operational flexibility make strategic asset any operation focused sustainability productivity By carefully analyzing material requirements production goals logistical needs businesses can select optimal configuration maximizes return investment while contributing greener built environment through effective resource reuse