Title: High-Capacity 750TPH Andesite Crushing Plant – Reliable Performance for Tough Applications

Industry Background

The global crushing equipment market is expanding. Demand comes from infrastructure and construction projects. Governments are investing in roads, railways, and urban development. This drives the need for high-capacity crushing plants. Efficient processing of hard materials like andesite is crucial. It ensures project timelines and cost control.

Product and Technology

A 750TPH andesite crushing plant is a heavy-duty system. It is designed for high-volume production.

- Primary Crushing: Uses a robust jaw crusher or gyratory crusher. It handles large andesite feed material.

- Secondary Crushing: A cone crusher is typically employed. It provides further size reduction.

- Tertiary Crushing: Another cone crusher or impact crusher may be used. It achieves the final product shape and size.

- Screening: Vibrating screens separate different aggregate sizes.

- Conveying: Belt conveyors transport material between stages.

Key technological features include:

- Heavy-Duty Construction: Components are built to withstand abrasive andesite.

- High Efficiency Motors: Reduce energy consumption per ton of output.

- Automation Systems: Monitor operations and optimize performance.

Key Equipment Configuration Example

| Equipment Type | Typical Model / Function | Key Feature for Andesite |

|---|---|---|

| Primary Crusher | Jaw Crusher | High manganese steel jaws for abrasion resistance |

| Secondary Crusher | Cone Crusher | Robust chamber design for consistent output |

| Tertiary Crusher | Cone Crusher / Impact Crusher | Fine shaping and cubical product generation |

| Vibrating Screen | Multi-deck Screen | Efficient sizing of final products (e.g., 0-5mm, 5-20mm) |

Market Trends & Applications

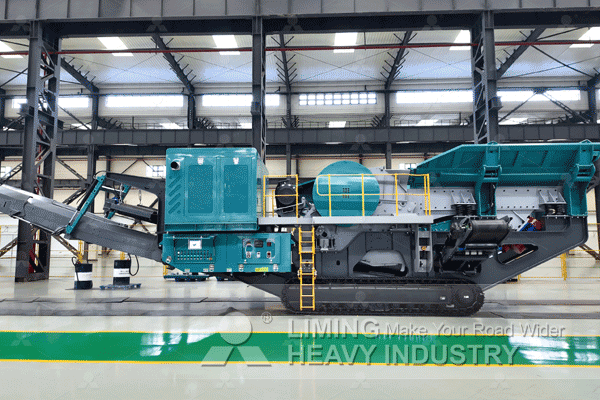

Demand is strong for high-capacity, mobile, and semi-mobile plants. They offer flexibility for large quarrying and mining projects.

Major application areas:

- Road Base Construction: Crushed andesite provides a stable foundation layer.

- Concrete Aggregate: High-strength concrete requires durable andesite aggregate.

- Railway Ballast: Andesite’s hardness makes it ideal for rail track support.

The industry is moving towards integrated, automated crushing circuits. This trend maximizes throughput and minimizes operational costs.

Future Outlook

The future of crushing focuses on sustainability and digitalization.

- Electric Drives & Hybrid Systems will lower carbon footprints.

- Predictive Maintenance using IoT sensors will reduce unplanned downtime.

- Advanced Automation will optimize production in real-time.

These innovations aim for higher efficiency with lower environmental impact.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a 750TPH plant?

A: Lead times vary but generally range from 6 to 9 months. This depends on specific configuration and customization.

Q: What after-sales support is available?

A: Comprehensive support includes installation supervision, operator training, and readily available spare parts supply.

Q: Can the plant be customized?

A: Yes. Plants can be tailored with different crusher types, screen configurations, or dust suppression systems to meet specific project needs.

Case Study

A major infrastructure project in Southeast Asia required a reliable aggregate supply.

- Challenge: Process extremely hard andesite at a sustained rate of 750 tons per hour. Meet strict particle shape specifications for high-grade concrete.

- Solution: A customized stationary crushing plant was deployed. It featured a primary jaw crusher, two secondary cone crushers, and two tertiary cone crushers with precision screens.

- Outcome: The plant consistently achieved over 750 TPH throughput. Final products perfectly met the concrete aggregate specifications. This ensured uninterrupted construction material supply for the project’s success.

Request a Quote Today

Need a reliable crushing solution for your project? Contact our experts now for a detailed proposal tailored to your specific requirements