Reliable level measurement of products with non-flat surfaces

Advanced technology to protect your process equipment

Process regulation with reduced installation and maintenance costs

1. Backgroud

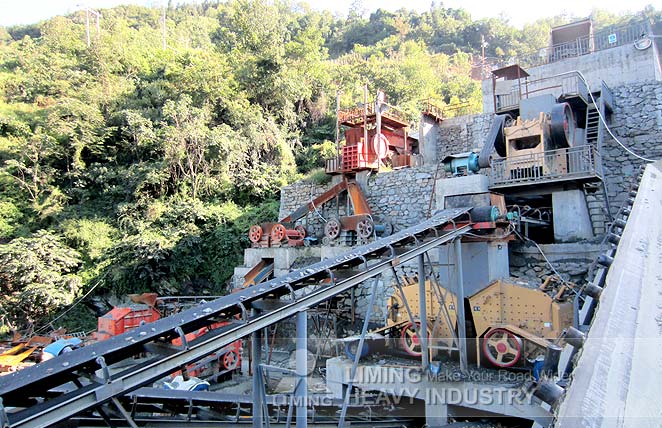

To obtain lime, the limestone is blasted from the quarry face before being broken down to a usable size, washed and taken on a conveyor belt to the kilns. Lime, also know as quicklime, is discharged from the kilns into hoppers from where it is then taken for further processing.

2. Measurement requirement

Lorries unload the limestone(grading sometimes>1m) onto an underpass, where a conveyor system transports the stone to a rock crusher. The conveyor need to be permanently covered with stone to prevent damage caused by reducing the load on the drive unit. Most conveyors are monitored by traditional ultrasonic devices. Those often have reliability and measurement issues due to the low reflectivity of big stones and the weak signal used in this technology, which is not efficient in dusty atmospheres. Once the stone is crushed into gravel(grading 10…30mm) it is washed and stored in silos before entering the calcination process. The uneven product surface makes it diffcult to obtain reliable level data without the use of antenna aiming kits.

If you would like to know more about the limestone quarry rock crusher, conveyor and silos, please Live Chat with our sales manager assistant.