A Comprehensive Guide on Mining Crushing Equipment

Introduction

Mining crushing equipment forms the backbone of the mineral extraction industry. Its primary function is to reduce the size of large, excavated rock and ore into manageable, smaller pieces for further processing. The efficiency and reliability of this equipment directly impact operational productivity, cost-effectiveness, and overall project viability. This guide provides a detailed overview of the different types of crushing machinery, their applications, and key selection criteria, offering a foundational understanding for industry professionals.

Primary Crushers: The First Line of Defense

Primary crushers handle the initial stage of size reduction, processing raw material directly from the mine face. These machines are engineered to accept very large feed material and deliver a coarse product. The most common type is the jaw crusher, which uses a fixed and a moving jaw to compress and break rock. Another prevalent type is the gyratory crusher, which features a conical head gyrating within a larger chamber, ideal for high-capacity crushing plants. Primary crushers are characterized by their robust construction and ability to process abrasive and high-strength materials with minimal preparation.

Secondary and Tertiary Crushers: Refining the Product

After primary crushing, the material often requires further reduction to achieve the desired particle size and shape. This is the role of secondary and tertiary crushers. Cone crushers are frequently used in these stages; they operate by compressing rock between a rotating mantle and a stationary concave liner. For producing finer materials or manufactured sand, impact crushers are highly effective. These machines use high-speed impact forces from hammers or blow bars to fracture the rock. The choice between these depends on the required product specification, such as cubicity for aggregate or fineness for mineral liberation.

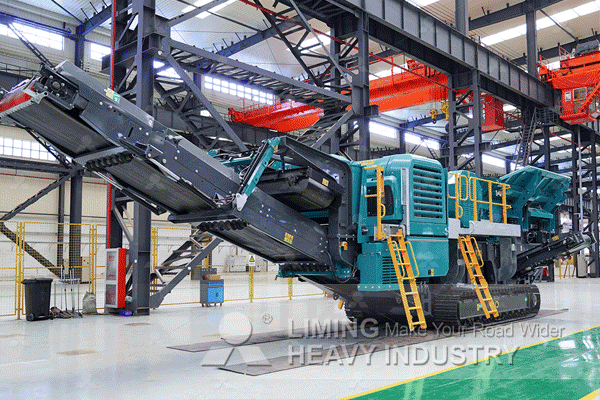

Mobile vs. Stationary Crushing Plants

A fundamental decision in any mining operation is choosing between mobile and stationary crushing plants. Stationary plants are permanent installations with high capacity and are best suited for long-term projects with a fixed feed source. They often involve complex infrastructure like conveyors and feed systems. In contrast, mobile crushing plants offer unparalleled flexibility. Mounted on tracks or wheels, they can be moved around a site or between sites relatively easily. This mobility reduces truck haulage costs and is ideal for shorter-term projects or operations with multiple scattered pits.

Key Selection Criteria for Optimal Performance

Selecting the right crushing equipment involves analyzing several critical factors.

- Material Characteristics: Hardness, abrasiveness, density, and moisture content of the ore significantly influence crusher choice.

- Feed Size and Required Product: The initial top size of the rock and the final product’s desired size distribution dictate the crusher type and number of crushing stages needed.

- Capacity Requirements: The plant’s required throughput (tons per hour) determines the size and model of the equipment.

- Operational Costs: Considerations include energy consumption, wear part replacement frequency, maintenance demands, and labor requirements.

Maintenance Strategies for Longevity

Regular maintenance is non-negotiable for ensuring crusher reliability and longevity. A proactive approach includes scheduled inspections of key wear parts like liners, mantles, jaws, and bearings. Monitoring systems that track parameters like pressure, temperature, and power draw can provide early warnings of potential problems. Proper lubrication is arguably the most critical routine task; using the correct lubricants at specified intervals prevents premature failure of critical components like bearings and gears.

Conclusion

The effective application of mining crushing equipment is a cornerstone of efficient mineral processing operations. Understanding the distinct roles of primary, secondary, and tertiary crushers allows for proper circuit design while weighing mobile versus stationary options ensures strategic alignment with project goals coupled with diligent maintenance safeguards this significant capital investment ensuring sustained productivity over its operational lifespan