Title: Your Premier Aggregate Crusher Plant Solution in Mexico

Industry Background

Mexico’s construction sector is expanding rapidly. Infrastructure development is a key driver. Urbanization fuels demand for raw materials. Government investments in public works are significant. The mining sector also requires robust crushing solutions. This creates a strong market for aggregate crusher plants.

Product and Technology

Modern crusher plants are highly efficient. They integrate several key components.

- Primary Crushers: Jaw crushers handle large rocks first.

- Secondary Crushers: Cone crushers provide further size reduction.

- Tertiary Crushers: Impact crushers create finely shaped aggregates.

- Screening Equipment: Vibrating screens separate aggregates by size.

Key technological features include:

- Automation Systems: Ensure consistent output and reduce labor.

- Energy-Efficient Motors: Lower operational costs.

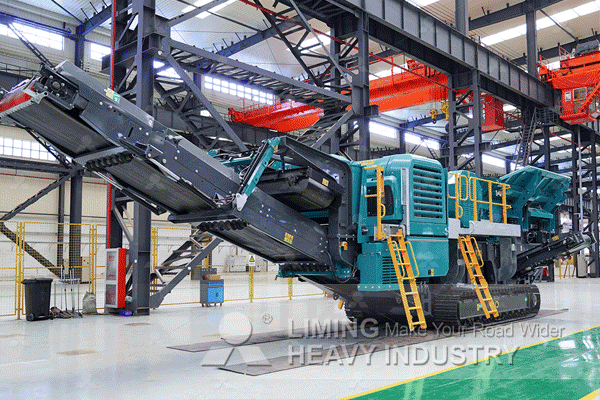

- Mobility Options: Track-mounted plants offer great flexibility.

- Dust Control Systems: Meet environmental regulations.

| Plant Type | Primary Use | Key Advantage |

|---|---|---|

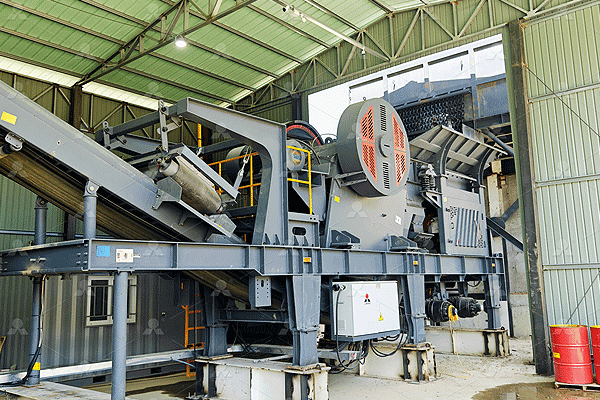

| Stationary Plant | Large, long-term quarry sites | High production capacity |

| Mobile/Tracked Plant | Multiple sites, compact spaces | Superior mobility and quick setup |

| Portable Plant | Temporary projects | Easy transport between locations |

Market Trends & Applications

Demand for high-quality aggregates is steady. The trend is towards mobile and compact plants. They are perfect for urban construction sites. Recycling construction waste is a growing application.

Main application areas:

- Road Construction: Requires base materials and asphalt aggregates.

- Building Construction: Needs sand, gravel, and crushed stone for concrete.

- Mining Operations: Crushes ore and minerals for processing.

Future Outlook

The industry is moving towards smarter solutions. Digitalization and IoT will enable predictive maintenance. Sustainability is a major focus. Plants will use more hybrid power sources. Automation will become standard to boost safety and output.

Frequently Asked Questions (FAQ)

-

What is the typical lead time for a new plant?

- Lead time varies from 8 to 16 weeks. It depends on the plant model and customization level.

-

Do you provide after-sales service and parts?

- Yes. We offer comprehensive after-sales support. A local stock of wear parts ensures minimal downtime.

-

Can the plant be customized for specific needs?

- Absolutely. We can customize screen configurations, crusher types, and conveyor layouts to match your material and output goals.

Case Study: Boosting Output for a Quintana Roo Contractor

A contractor in Quintana Roo faced low production rates. Their old plant could not meet project deadlines.

Challenge: Increase aggregate production for a new hotel complex. The site space was limited.

Solution: We supplied a medium-capacity mobile jaw crusher plant. Its compact design fit the site perfectly. Setup was completed in less than two days.

Outcome: Production increased by 40%. The project stayed on schedule. The client saved significantly on hauling costs.

Ready to Upgrade Your Operation?

Maximize your productivity and profits with the right equipment. Contact us today for a free consultation and a personalized quote for your aggregate crushing needs in Mexico.

[Contact Us Now for a Custom Quote]