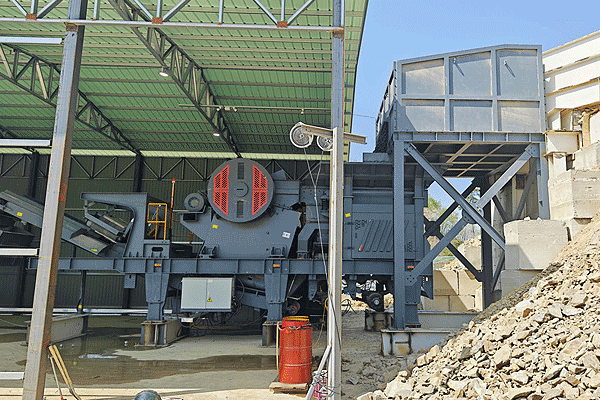

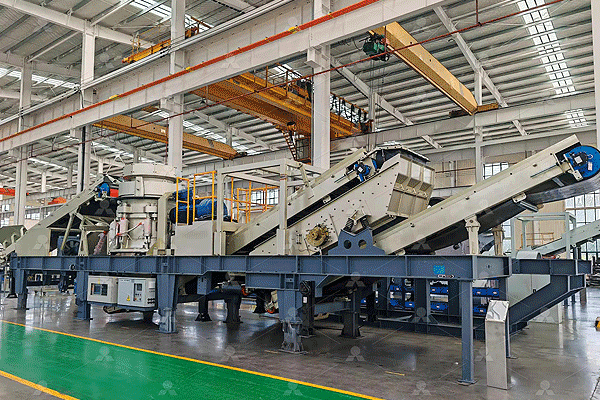

The C6X Mobile Crusher: A Powerful Solution for 200 TPH Granite Processing

Introduction

Granite is one of the most widely used construction materials due to its durability, aesthetic appeal, and versatility. Processing granite efficiently requires robust crushing equipment capable of handling high production demands while maintaining operational flexibility. The C6X mobile crusher stands out as an ideal solution for granite processing, offering a crushing capacity of up to 200 tons per hour (TPH). This article explores its key features, advantages, applications, and maintenance considerations.

Key Features of the C6X Mobile Crusher

The C6X mobile crusher is designed for high-performance crushing operations, particularly suited for hard materials like granite. Some of its standout features include:

- High Crushing Capacity: With a throughput of up to 200 TPH, it ensures efficient processing even in demanding quarrying and mining environments.

- Robust Construction: Built with high-strength steel and wear-resistant components, it withstands the abrasive nature of granite without compromising durability.

- Advanced Crushing Technology: Equipped with optimized jaw plates and a deep crushing chamber, it maximizes material reduction while minimizing energy consumption.

- Mobility & Flexibility: Its track-mounted design allows easy relocation between job sites, reducing downtime and transportation costs.

- Automated Control System: Integrated sensors and smart controls optimize performance while reducing manual intervention.

These features make the C6X crusher a reliable choice for contractors seeking productivity and efficiency in granite processing.

Advantages Over Traditional Crushing Solutions

Compared to stationary crushers or older mobile models, the C6X offers several distinct benefits:

- Reduced Operational Costs – Its fuel-efficient engine lowers running expenses while maintaining high output levels.

- Quick Setup Time – Unlike fixed plants requiring extensive installation, this crusher can be operational within minutes after arrival on-site.

- Lower Environmental Impact – Advanced dust suppression systems minimize airborne particles, complying with stricter environmental regulations.

- Versatile Material Handling – While optimized for granite, it can also process other hard rocks like basalt and quartzite without major adjustments.

- Improved Safety Features – Emergency stop functions and remote monitoring enhance operator safety during prolonged operations.

These advantages make it an attractive option for businesses looking to modernize their crushing operations without sacrificing reliability or efficiency.

Applications Across Different Industries

The versatility of the C6X mobile crusher extends beyond quarrying—it serves multiple industries requiring efficient rock processing:

Construction & Road Building

Crushed granite is essential in producing concrete aggregates and road base materials; this machine ensures consistent sizing crucial for structural integrity in infrastructure projects.

Mining Operations

In mineral extraction sites where space constraints exist due to tunneling or pit depth limitations—mobile units provide unmatched adaptability compared to stationary setups.

Recycling & Demolition Waste Processing

Although primarily designed for natural stone crushing—modified configurations allow repurposing demolished concrete structures into reusable construction material further enhancing sustainability efforts across urban redevelopment zones worldwide.

Each application benefits from rapid deployment capabilities combined with sustained high-output performance ensuring profitability regardless if used short-term contracts long-term projects alike!

Maintenance Tips Ensuring Longevity And Efficiency

To maximize service life while minimizing unexpected breakdowns follow these best practices when operating your unit:

- Regularly inspect wear parts such as jaw plates liners replace them before excessive deterioration occurs preventing damage underlying components.

- Lubricate moving parts according manufacturer recommendations avoiding premature bearing failures common harsh working conditions.

- Clean dust debris accumulation around hydraulic systems electrical panels preventing overheating malfunctions during extended shifts.

- Monitor engine oil coolant levels daily especially extreme temperature environments safeguarding against costly repairs later stages usage cycle.

- Train operators proper handling techniques reducing unnecessary strain machinery prolonging intervals between major overhauls significantly cutting lifetime ownership expenses substantially!

Adhering routine checks not only enhances reliability but also maintains peak productivity throughout entire lifespan investment ultimately delivering better return capital employed versus competitors still relying outdated technologies today’s fast-paced market demands!

This article provides comprehensive insights into why choosing a well-engineered solution like the [C6X] proves advantageous across various sectors needing dependable yet flexible approaches toward large-scale rock fragmentation tasks efficiently economically sustainably moving forward future developments industry standards evolve continuously over time!