Choosing the Right Crusher for Rock, Stone, Concrete, and Mineral

Selecting the appropriate crusher is essential for efficient material processing in construction, mining, and recycling industries. Different materials—such as rock, stone, concrete, and minerals—require specific crushing mechanisms to achieve optimal results. This guide explores key considerations when choosing a crusher without focusing on particular brands or models.

Understanding Material Properties

Before selecting a crusher, analyze the material’s hardness, abrasiveness, moisture content, and size distribution. Harder materials like granite demand robust crushers with high wear resistance, while softer limestone may require less aggressive crushing mechanisms. Moist or sticky materials can cause clogging in certain crushers, necessitating specialized designs. Additionally, consider whether the material contains impurities that could affect crushing efficiency.

Types of Crushers and Their Applications

Different crushers excel at processing specific materials:

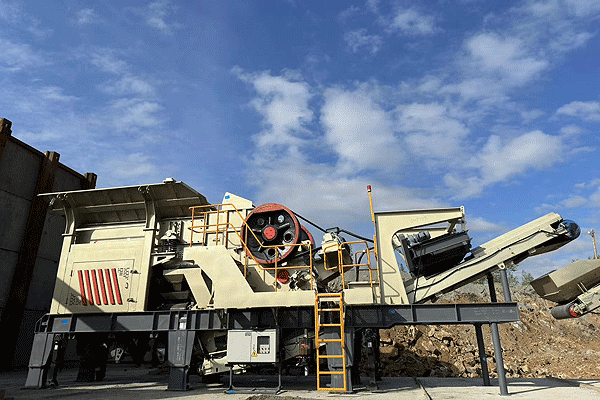

- Jaw Crushers: Ideal for primary crushing of hard rocks and stones due to their strong compression force.

- Impact Crushers: Suitable for softer materials like limestone or recycled concrete because they use impact force rather than pressure.

- Cone Crushers: Efficient for secondary crushing of medium-hard minerals with consistent particle size requirements.

- Gyratory Crushers: Best suited for large-scale mining operations processing high volumes of hard rock or ore.

Each type has trade-offs between throughput capacity and final product shape—choose based on project needs.

Assessing Production Requirements

Determine required output size (fine aggregate vs. coarse fragments) and hourly production volume before selecting equipment. High-capacity projects benefit from stationary crushers with continuous feeding systems; smaller operations may prefer portable units offering flexibility but lower throughput speeds—balance efficiency with mobility based on site conditions such as space constraints or frequent relocation demands during phased projects like road construction where mobility matters greatly alongside consistent performance metrics over timeframes spanning months rather than days alone!

Maintenance Considerations & Operational Costs

Crushing equipment requires regular upkeep—wear parts replacement schedules vary significantly depending upon usage intensity plus environmental factors including dust exposure levels impacting lubrication effectiveness long-term durability concerns arise if neglected maintenance leads unexpected downtime costly repairs outweigh initial savings cheaper models might provide upfront yet fail deliver sustained reliability under heavy workloads typical quarry environments present challenges requiring durable solutions designed withstand harsh operating conditions without frequent breakdowns disrupting workflow unnecessarily increasing total ownership expenses dramatically across lifespan investments made wisely upfront pay dividends later stages project execution phases ensuring smooth uninterrupted progress timelines adhered strictly avoiding delays penalties associated missed deadlines contractual obligations fulfillment expectations met consistently throughout engagement period duration extended beyond original scope unforeseen circumstances necessitate adaptability planning contingencies place beforehand mitigate risks proactively instead reactively addressing issues after occurrence minimizes disruptions maximizes productivity overall success achieved desired outcomes realized fully satisfaction stakeholders involved process completion milestones reached successfully conclusion efforts rewarded appropriately recognition contributions made team members collectively working towards common goal shared vision driving forward momentum sustained continuously until final deliverables handed over client sign-off obtained officially marking end chapter beginning new opportunities horizon awaiting exploration future endeavors undertaken confidently lessons learned applied effectively next venture embarked upon renewed vigor determination succeed once again proving capabilities time tested methodologies refined perfected practice makes perfect indeed!