CI5X Impact Crusher: A Cost-Effective Solution for Gypsum Mining at 120 TPH

Introduction to the CI5X Impact Crusher

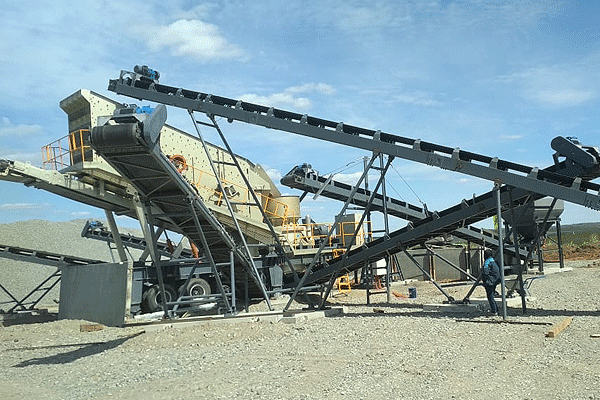

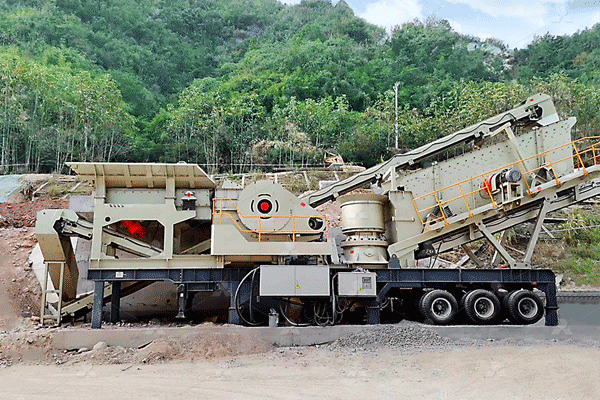

The CI5X impact crusher is a high-efficiency crushing machine designed for medium-hard materials like gypsum. With a capacity of 120 tons per hour (TPH), it meets the demands of modern mining operations while maintaining low operational costs. Its robust construction and advanced crushing technology make it ideal for processing gypsum ore into uniform particles, ensuring high productivity in mining applications.

Unlike traditional crushers, the CI5X model integrates hydraulic adjustment and impact-resistant components, reducing downtime and maintenance expenses. Its adaptability allows seamless integration into existing production lines, making it a preferred choice for gypsum processing plants seeking efficiency and reliability.

Key Features Enhancing Performance

The CI5X impact crusher stands out due to several innovative features:

- High Crushing Efficiency: Optimized rotor design ensures maximum material impact, increasing throughput while minimizing energy consumption.

- Hydraulic Adjustment System: Enables quick gap setting changes for different particle sizes without stopping production.

- Wear-Resistant Components: Reinforced blow bars and liners extend service life, reducing replacement costs in abrasive environments like gypsum mining.

These features collectively enhance operational stability, ensuring consistent output quality even under heavy workloads. The machine’s intelligent monitoring system further aids in real-time performance tracking, preventing unexpected failures.

Factory Price Advantage

One of the most attractive aspects of the CI5X crusher is its competitive factory pricing. Unlike premium models from famous brands, this crusher delivers comparable performance at a fraction of the cost. Manufacturers prioritize affordability without compromising durability, making it accessible to small and mid-sized gypsum mining operations.

Lower acquisition costs translate to faster ROI (Return on Investment), particularly beneficial for businesses aiming to scale production without excessive capital expenditure. Additionally, simplified maintenance requirements contribute to long-term savings on labor and spare parts.

Applications in Gypsum Mining

Gypsum mining demands equipment capable of handling brittle materials efficiently. The CI5X impact crusher excels in primary or secondary crushing roles, producing uniformly sized aggregates suitable for further processing into plasterboard or cement additives. Its ability to handle moist or sticky gypsum—without clogging—ensures uninterrupted operation in challenging conditions.

For mines targeting 120 TPH output, this crusher offers an optimal balance between capacity and operational flexibility, supporting sustainable production growth while adhering to environmental regulations through reduced dust emissions and noise levels compared to older models.

Conclusion: A Smart Investment

The CI5X impact crusher presents a compelling solution for gypsum miners seeking reliable performance at an economical price point. Its advanced engineering minimizes downtime while maximizing output quality—key factors driving profitability in competitive markets. By choosing this model over higher-priced alternatives from famous brands, operators can achieve cost-effective scalability without sacrificing efficiency or durability—a decisive advantage in today’s resource-intensive industries.