Portable Cone Crushers: A Practical Solution for Russia’s Concrete Recycling Needs

Introduction to Portable Cone Crushers

Portable cone crushers are versatile machines designed to process hard and abrasive materials, including concrete, into smaller, reusable aggregates. Their compact design and mobility make them ideal for Russia’s vast and often remote construction sites. Unlike stationary crushers, these units can be easily transported between job sites, reducing downtime and logistical challenges. With Russia’s growing emphasis on infrastructure development and sustainable construction practices, portable cone crushers offer an efficient way to recycle concrete waste on-site.

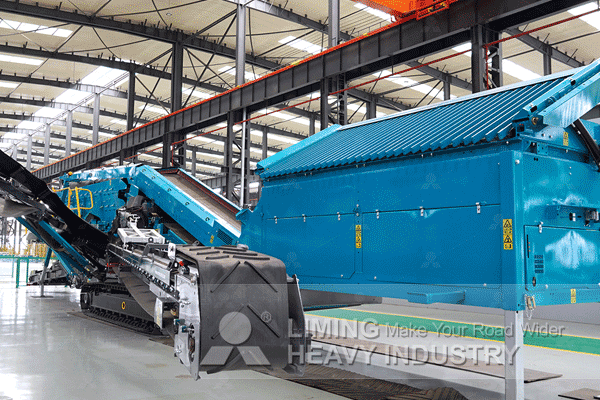

Key Features of Portable Cone Crushers

Modern portable cone crushers are equipped with advanced features that enhance productivity and ease of use. Hydraulic adjustment systems allow operators to quickly modify the crusher’s settings for different material sizes. High-performance crushing chambers ensure consistent output quality, while robust chassis designs provide stability during operation. Many models also include integrated screening systems, enabling simultaneous crushing and sorting of materials. These features make portable cone crushers particularly valuable in Russia’s demanding climate and terrain conditions.

Applications in Concrete Recycling

In Russia, concrete recycling is gaining traction as a cost-effective and environmentally friendly solution for construction waste management. Portable cone crushers play a crucial role by breaking down demolished concrete into reusable aggregate for new projects. This reduces the need for virgin materials and minimizes landfill waste. Common applications include road construction, foundation work, and urban redevelopment projects where space constraints favor mobile equipment over fixed installations.

Advantages Over Traditional Crushing Methods

Compared to stationary crushing plants, portable cone crushers offer several advantages in the Russian market. Their mobility eliminates the need for costly material transportation between demolition sites and processing facilities. Quick setup times allow contractors to begin operations almost immediately after arrival at a site—a significant benefit given Russia’s short construction seasons in many regions. Additionally, their fuel-efficient engines lower operational costs while complying with increasingly stringent emissions regulations.

Challenges and Considerations

Despite their benefits, portable cone crushers face challenges in Russia’s harsh operating environments. Extreme temperatures can affect machinery performance if proper maintenance is neglected. Operators must also ensure that feed materials are free from contaminants like rebar or wood, which could damage internal components. Selecting a model with adequate power and durability is essential to withstand the demands of large-scale concrete recycling projects prevalent in Russian cities such as Moscow or St. Petersburg.

Future Outlook

As Russia continues investing in infrastructure upgrades and sustainable construction practices, demand for portable cone crushers is expected to rise further advancements automation technology may soon enable remote monitoring predictive maintenance further enhancing efficiency ruggedness these machines overall they represent smart investment contractors looking streamline operations while supporting environmental goals conclusion adoption this equipment likely accelerate coming years across country diverse regions